The story of N-Amylmethylamine ties right into the larger arc of organic chemistry’s post-war boom. Chemists back in the 20th century began tapping into the vastness of amine compounds, pushing beyond traditional methylamines and ethylamines. N-Amylmethylamine caught the attention of synthetic chemists for its straight-forward alkyl chain mixed with a methyl group. Demand ticked upward during the 1970s as specialty chemicals and custom synthesis found new uses in research labs, especially as pharmaceutical industries hunted for intermediates that expand molecular diversity. Bench scientists saw how shifting from simpler amines to options like N-Amylmethylamine could unlock new reaction routes, tweak pharmacokinetics, and offer better yields when they sought to build novel molecules. Its relevance proved lasting, folding into both industrial and academic spheres where niche chemistry sometimes spins out game-changing discoveries.

N-Amylmethylamine sits as a colorless to pale-yellow liquid, noticeable for its pungent odor the moment you crack open the bottle. Unlike some specialty amines with annoying volatility, it brings a middle-ground volatility, which means spills vanish pretty quickly, but the residue lingers just enough to keep lab workers aware. Its molecular makeup (C6H15N) sees it landing between the lighter methylamines and the heavier, bulkier alkylamines. This blend gives it a useful set of properties: it slips into reactions as both a nucleophile and a mild base, and those longer alkyl chains make it more compatible with organic solvents. Over time, suppliers have packaged it in both bulk drums and specialty glass ampoules, all while tweaking availability between industrial-grade and purer lab standards.

N-Amylmethylamine’s main draw shows up in its physical characteristics. It’s got a boiling point around 130-135°C, right where you want it for reactions that run at a gentle reflux. It dissolves well in organic solvents like ether and benzene and still mixes modestly with water thanks to the methylamino group. Its density falls near 0.77 g/cm³ at room temperature, making it lighter than water but heavier than the lightest alkanes. Chemical stability stands out—the amine holds up against hydrolysis or oxidation under normal storage, but contact with strong acids or chloroform leads to aggressive reactions. Pairing it with strong oxidizers is a headache, since it can form hazardous byproducts, including nitrosamines, which toxicologists frown upon. This mix of traits explains why it’s carved out a consistent, if not glamorous, place in synthesis shops and R&D setups.

Walk into any lab and the bottle will read something like “N-Amylmethylamine, ≥98% purity, CAS No. 624-78-2.” Manufacturers stamp hazard diamonds for flammability and acute toxicity, plus the standard “Avoid breathing vapors” warning. Packaging standards require HDPE, glass, or steel to keep out atmospheric moisture—this amine has a stubborn habit of dragging in water if left open. Most safety data sheets outline a flash point near 30°C, aligning with other light amines, which influences how storage cabinets are set up, especially in hotter climates. Impurity profiles, especially traces of other amines or aldehydes, get tight regulation in the research context. In the pharmaceutical arena, even trace nitrosamines face rejection, so top suppliers invest in refined purification and batch tracking to reassure buyers down the supply chain. Lab managers and safety officers get accustomed to spotting those labels, and everyone works around the quirks these specifications demand.

Synthetic routes for N-Amylmethylamine lean on classic chemistry methods that many organic chemists learned right after Grignard reactions. The most common pathway involves reductive amination of n-amylaldehyde with methylamine in a hydrogen atmosphere, using a catalyst such as Raney nickel or palladium on carbon. This approach offers clean conversion if temperature and pressure sit in the sweet spot—too cold and yields drop, too hot and you start picking up dialkylated byproducts. Another method employs alkyl halides; pairing n-amyl bromide with methylamine under basic conditions works, though you’ve got to babysit the reaction to dodge over-alkylation. Both techniques require careful solvent handling—improper separation means pulling an oily mess through purification, which nobody enjoys. The ease of scale-up using these methods keeps N-Amylmethylamine available for both big tanks and modest bench tops.

N-Amylmethylamine steps up in alkylation, acylation, and condensation reactions with few complaints. Its nucleophilic nitrogen kicks off reactions with acid chlorides and anhydrides to yield amides, a valuable trick for medicinal chemists designing new drugs. Its primary amine is eager for Schiff base formation with carbonyl compounds, which opens up everything from ligands in metal complexes to key intermediates in custom catalysts. Adding one carbon here or swapping the chain there lets chemists generate libraries of analogs without starting from scratch. It’s also handy in Michael additions and for building more complicated heterocycles, a reason research groups still order it for new reaction screening. This flexibility gives it a longer shelf life on the chemical menu than some rare or more expensive intermediates.

Browse catalogs and you'll see N-Amylmethylamine hiding behind names like 1-Methylaminopentane, Pentylmethylamine, or N-Methylpentan-1-amine. Regional variation in nomenclature pops up, especially as smaller suppliers chase emerging markets or tailor to local industrial preferences. CAS numbers clear up confusion—telling buyers that 624-78-2 stands for the same molecule, regardless of how the label reads. Specialty use industries sometimes invent their own codes, tacking on internal batch numbers or pharmaceutical reference IDs, a nod to the practical reality that language changes but the chemistry doesn’t. Inside the business, conversations skip straight to “N-methyl amylamine” or just “the six-carbon methylamine” to keep things moving.

Safety officers treat N-Amylmethylamine as slightly more hazardous than short-chain amines, mostly from inhalation risk and mild skin irritation. Reports from manufacturing sites point out eye irritation and headaches if exposure isn’t cut off quickly. Direct contact calls for standard PPE: gloves, goggles, and preferably splash aprons in settings with splashing hazards. Good ventilation remains non-negotiable, since the vapors start collecting at concentrations well below the occupational limits in most countries. Fire codes trigger storage limits in commercial labs, and spill kits have to be ready for both flammability and chemical burns. Emergency protocols—wash with water, move to fresh air, seek medical attention—mirror those of similar organics. Waste handling involves neutralizing before disposal, since untreated drains can carry it straight into the watershed. Real-world incidents, rare though not impossible, drive home the importance of keeping the basics in mind every day.

Pharmaceutical researchers find N-Amylmethylamine valuable for building intermediate structures. Its role shows up most in pilot projects, where tweaking basic amine length affects drug absorption and solubility. Agrochemical companies turn to it for manufacturing specialty herbicides and fungicides, because that extra methyl group often changes how a molecule interacts with plant enzymes. In the world of materials science, its presence in making surfactants and corrosion inhibitors makes it less visible to the public but important to countless products sitting on hardware store shelves. Analytical chemists set it up as a standard for chromatography calibration, especially in testing volatile amines in environmental samples. Some synthetic dye houses include it in pigment manufacturing, drawn by its reliable reactivity. No matter the field, specialists eventually spot it as a way to dial in, rather than overhaul, molecular properties.

Journal articles continue to roll out data on N-Amylmethylamine’s reactivity and structure-activity relationships. Med chemists publish about using it to fine-tune the lipophilicity of candidate drugs, seeking optimal transport across cell membranes. Analytical scientists push for better detection of trace amines in food and the environment, sometimes using isotopically labeled versions. One trend in R&D involves computational approaches, simulating how N-Amylmethylamine derivatives behave before running expensive experiments. The move toward greener chemistry means alternative synthetic routes are under investigation—like swapping out toxic reducing agents in favor of biocatalytic or electrochemical steps. Scale-up trials at the pilot-plant level spark feedback between development and production, teaching both sides how to manage stability and purity when batches jump from milliliters to liters. Critics sometimes voice concerns about regulatory complexity, yet the persistent R&D pipeline keeps it relevant.

Toxicologists dig into both acute and chronic hazards. Inhalation causes mucous membrane irritation, headaches, and sometimes dizziness; animal studies confirm dose-dependent toxicity impacting the liver and central nervous system. Low-dose, chronic exposure brings up questions over potential carcinogenicity, especially where nitrosamine byproducts come into play. Regulatory agencies flag this group, and part of ongoing research looks at removing nitrosamines from both product and waste streams. Lab data show relatively low dermal penetration, but the compound can sensitize some workers, prompting shifts in workplace standards in places like the EU and California. Wastewater studies examine breakdown products, pointing out the need for better filtration before disposal. Academic groups call for expanded chronic toxicity trials and longer-term animal studies, wanting a more complete account of both direct and degradation-related risks.

Looking ahead, N-Amylmethylamine appears set for another chapter built on specialty markets and evolving regulation. Growth comes from designers of new drugs, as each ring or chain tweak brings hopes of more potent or safer therapies. Sustainability concerns push both manufacturers and consumers to focus on cleaner synthesis, waste management, and improved recycling, possibly using enzyme-based or electrochemical alternatives. Digital modeling, especially AI-driven reaction prediction, already helps in designing next-generation derivatives and in planning more efficient manufacturing. At the same time, governments lean toward tighter safety and environmental rules, which means companies must put safety and traceability front and center. The need for low-toxicity, reasonably priced organic building blocks won’t shrink—N-Amylmethylamine’s blend of reactivity and manageability keeps it on the chemist’s shelf, ready for whatever new project comes next.

N-Amylmethylamine sounds like something straight out of a lab, the kind of word you might skip past in a science textbook. But in reality, this chemical finds its way into daily life in ways most people never consider. Over the years, working alongside folks in industrial and laboratory settings, I’ve seen how often unfamiliar names like this hide real-world significance.

The most direct use of N-Amylmethylamine pops up in the chemical industry. It serves as a building block for other, more complicated compounds. Manufacturers use it because it reacts dependably and offers specific properties that can’t always be found in similar amines. Sometimes, small tweaks in a compound give products the edge they need—stronger plastics, longer-lasting resins, or adhesives that hold in tough environments. I remember a project where switching to a related amine altered the outcome completely; the smallest molecular detail can reshape a whole process.

Medicinal chemistry often leans hard on molecules like N-Amylmethylamine. Making a new drug isn’t just about finding a molecule that “works”—it’s about getting the right reactions at the right times. N-Amylmethylamine makes a useful tool when building up active pharmaceutical ingredients. Customizing the molecule’s side chain allows for better tailoring of how the final medicine acts in the body, whether through improved absorption or more precise targeting of tissues.

Farmers rarely hear about the exact ingredients mixed into fertilizers and pesticides, but back in the design phase, folks working behind the scenes decide what goes into the final product. N-Amylmethylamine’s structure lets it slip into agrochemical formulas to change how a compound dissolves or spreads. This can end up saving crops or cutting waste. I once saw a study where a small change in a pesticide’s amine component sharply reduced how much ended up in groundwater—environmental wins sometimes rest on these invisible choices.

One thing I’ve learned through experience is that handling chemicals with long names isn’t just for scientists in hazmat suits. N-Amylmethylamine, like a lot of its cousins, gives off strong fumes. If dealt with carelessly, it can irritate lungs and skin. The answer isn’t just shutting the stuff away, but making personal protection and proper storage non-negotiable. I’ve watched both careful handling and risky shortcuts, and the difference is obvious—simple safety measures keep accidents from becoming headlines.

Relying on specialty chemicals often creates tough questions for manufacturers and the planet. Shipping and storing these tools uses energy, and spills or leaks can carry risks. Looking forward, research labs continue to test greener alternatives, aiming to swap out traditional chemicals for those that break down faster or pose less hazard. Chemists tinker with N-Amylmethylamine’s structure to unlock improvements, lower disposal costs, and make the workplace a safer space.

Most people won’t ever order a drum of N-Amylmethylamine or see its name on a package. Still, it’s one of many unsung ingredients that help shape safer medicines, more durable materials, and better-performing agricultural tools. Tracing these connections keeps us alert to the invisible work that goes into keeping the world moving, one long chemical name at a time.

Some folks look at a chemical name and simply see a wall of letters. But grab a close look at “N-Amylmethylamine” and you’ll find more than chemistry jargon—you’ll spot clues about structure and real-world use. N-Amylmethylamine is an organic compound that pops up where specialty amines get used, especially in the world of flavor, fragrance, and fine chemicals work.

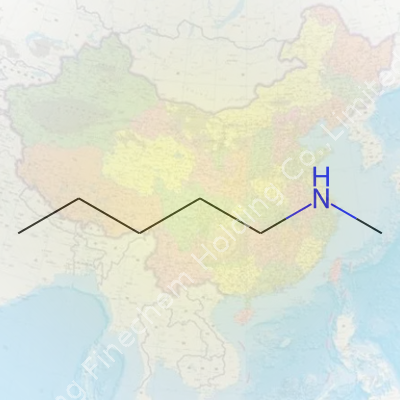

Its formula reads as C6H17N. Reading that out gives you one nitrogen atom, seventeen hydrogens, and six carbons. This isn’t some exotic formula only a chemist can appreciate. Try sketching it out, and you’ll map a straight chain built from five carbons (that’s the amyl piece), tethered by a nitrogen, and capped with a methyl group at the end. It almost looks like a cousin to simpler amines many learn about in high school labs, just with a longer tail tacked on.

Molecular weight doesn’t just belong on a safety sheet—it’s the cornerstone for every lab and plant calculation that follows. N-Amylmethylamine weighs in at 103.21 g/mol. For anyone working with grams, beakers, and balances, this number shows up on the scale every day. You can’t dose a reaction or blend a batch without knowing it. Try making any calculation with a mystery weight and you’ll soon realize your math, and results, will be way off.

Sizing up those elements, carbon clocks in at 12.01, hydrogen pitches in at 1.01, and nitrogen weighs 14.01. Multiply and add it up: 6×12.01 for carbon, 17×1.01 for all the hydrogens, tack on 14.01 for nitrogen—you land at that precise value. It’s not just trivia; it’s the kind of arithmetic that keeps production lines running.

There’s a lot of chatter about chemistry safety, regulations, and handling, but none of it counts unless someone understands the basics down to the ground. Miss the mark on a formula and a simple miscalculation becomes a costly recall or a safety incident. At small scales, chemists double-check these details to prevent wasted time and ruined experiments. At larger operations, the risk of error rises, and so does the cost. In my own lab work, skipping a double-check on a formula or overlooking a molecular weight meant wasted hours and thrown-out batches. Accuracy saves everyone some headache.

N-Amylmethylamine sparks interest in some circles due to its role in making specialty chemicals. Some research groups dig into its reactivity, while flavor developers see it as another building block in a vast array of custom scents and tastes. That means more attention lands on regulatory requirements and safe handling. Even on the job, chemicals like this show up in custom orders from large flavor houses. When strict labeling and composition rules show up, knowing the right formula and molecular weight stops legal headaches before they begin.

One step to stop slip-ups is quality training. Onboarding for lab workers and plant staff should always cover the methods of confirming formulas. Simple checklists help, but practiced habits go further. Double-check molecular weights before ordering or mixing. Keep updated databases handy. If working with N-Amylmethylamine—or any other compound—turn to supplier specs or trusted resources rather than copying from memory.

Software and apps have made life easier, but it’s tempting to get lazy and trust whatever autofill offers. When regulators are reviewing a facility, or when customers rely on what’s printed on a label, these basics matter. Keep those numbers front and center and cut down on the chance of costly mistakes. The details—sometimes they look small, but their impact is huge.

Anyone who has worked in a lab or warehouse knows that some chemicals demand respect. N-Amylmethylamine carries its own set of risks. This is an organic compound often used in research and chemical synthesis, and its odor alone can clear a room. It doesn’t play nice with air or water for long, and once it spills, headaches start—sometimes literally.

Keeping N-Amylmethylamine secure is not just a checkbox exercise. I have seen storage mistakes bite back hard. Once, after staff ignored a leaky seal, someone opened the cabinet and got a faceful of fumes. Eyes watered, the fire alarm blared, and work ground to a halt for hours.

This is a liquid that reacts strongly with oxidizing agents and acids. Forgetting to check container compatibility means risking everything from ruined experiments to fire hazards—or in a worst-case scenario, sending people to the hospital. Small lapses create real danger.

Choosing the right container protects everyone. Avoid plastics that soften or crack easily. Stainless steel or glass with tight-fitting, properly labeled caps wins every time. Don’t count on just a casual shelf—dedicated cabinets that seal out moisture and light make a difference. This chemical doesn’t need sunlight or fluctuating temperature messing with it.

Some colleagues grew careless and stacked incompatible chemicals on top of each other, thinking nothing would happen. After a bottle leaked, cleanup took an entire afternoon. Segregating N-Amylmethylamine from acids, strong oxidizers, and food items saves time and money in the long run. Flammable cabinets aren't overkill; they're insurance.

Gloves, goggles, and lab coats aren’t suggestions—they’re basic gear. I once thought a quick transfer didn’t need much protection, only to feel skin irritation before lunch. Vapors move fast: proper ventilation pulls them away before they have a chance to linger. If fume hoods are available, use them. Your nose and lungs will thank you.

Trainings stick in your mind after a real scare. I remember a spill drill led by a seasoned safety officer. We practiced neutralizing and containing leaks using absorbent pads and an appropriate spill kit. The trick is quick action—don’t hope a small puddle will disappear on its own. Call for backup if things escalate. Information like the safety data sheet should always be within reach, even for the seasoned crew.

People tend to get casual after a while, but N-Amylmethylamine won’t cut you slack. Watching a rookie pour too quickly proved messy, and a minor splash landed on the bench. No one felt like cleaning up chemical burns. A couple of minutes to double-check everything beats a day filling out accident reports.

Shortcuts don’t pay off in real-world labs and stockrooms. Regular inspections make a world of difference. Relying on habits—like always capping bottles, storing chemicals by hazard class, and logging each use in a notebook—keeps memories of near misses fresh. Sharing stories about what goes wrong encourages new folks not to skimp on basics.

There’s a reason seasoned staff stay sharp around N-Amylmethylamine. Safe storage and careful handling are more about building a culture than following rules. Sticking to them means everyone gets home on time—without scars or stories best left untold.

I’ve always thought the quiet details—like container size—end up shaping a project just as much as the main ingredient. For N-Amylmethylamine, a chemical floating through different industries from pharma labs to specialty manufacturing, practical packaging can cut out wasted time and cash. Every business I’ve worked in, from the small-batch research shop to the scale-up production floor, had its own dance with space, safety, and handling. No one format solves it all.

Across suppliers, N-Amylmethylamine doesn’t follow a one-size-fits-all rule. Most folks in the lab go for the smaller glass bottles, usually in the 100-mL or 250-mL range. These sit well on a benchtop, and you get just enough product to run your experiments with minimal waste. Glass holds up against this compound’s quirks, so you won’t find yourself cleaning up an ugly spill or dealing with leaching plastics.

Move up to a busy chemistry department or a pilot plant, and the 500-mL or 1-liter bottles get the call. Sturdy caps, clear labels—little things like that reduce mixups. No one wants to hit a roadblock in the middle of calibration because they couldn’t read what was supposed to go into the batch. I’ve seen operations lose days over something as simple as the wrong jug showing up—or worse, cracking open a size they couldn’t store safely.

Bulk buyers step into a different lane. Here, suppliers will line up choices like 5-liter, 10-liter, or even 25-liter high-density polyethylene or steel drums. These containers land in the warehouse with every inch carefully calculated for stacking and hazard controls. The drum option makes the most sense for those running processes on the daily, because it shaves off handling costs and cuts down on constant purchase orders. It also let teams schedule deliveries around their workflow instead of rushing to restock every week.

From personal experience, the choice never hangs solely on volume. Safety is a forever companion—N-Amylmethylamine carries flammable and corrosive risks. Small bottles lower spill chances, making them friendly to tight lab benches. Larger drums, if you don’t have a way to ventilate or contain leaks, can flip from efficient to dangerous in a heartbeat. Regulatory rules tighten as quantity rises, making paperwork and storage rules trickier with each size bump.

I’ve watched teams debate cost savings from buying in bulk only to pay it all back in extra permits and training. Take stock of team size, security tools, space for secure lockers or cooling. Suppliers will sometimes help with returnable drums, which spares you disposal headaches. That’s earned a thumbs-up from environmental managers I’ve worked alongside.

The biggest wish from the people using N-Amylmethylamine day to day isn’t always a cheaper price—it’s better information. Too often, a spec sheet buries the details on what kind of container fits what. Tighter supplier communication, clear labeling, and some flexibility—like short-run intermediate sizes—would keep planning headaches away.

Smarter packaging is more than a nice-to-have. It keeps costs down, sharpens safety, and lets people from different backgrounds—R&D, scale-up, or logistics—work toward the same result: getting the job done without accidents, waste, or delays.

Purity sounds fancy, but for anyone working in a lab or an industrial setting, it comes down to one thing: can you trust what you’re buying? N-Amylmethylamine isn’t a household name, though in several fields—from pharmaceutical research to specialty polymers—demand for it crops up. The biggest questions revolve around trace contamination and how clean the sample really is.

Suppliers like Sigma-Aldrich, TCI, and Alfa Aesar do carry N-Amylmethylamine. Many are open about their purity grades, especially on safety data sheets and catalogs. Grades like 98%, 99%, and sometimes even higher end up listed online. That's good, but labels mean a lot less if you can’t double-check each batch. From experience, catalog values can drift based on old stock, batch issues, or storage mishaps.

Pure compounds often come with a certificate of analysis (CoA). Without that, trust goes out the window. Most serious suppliers offer a CoA if you ask, but not all default to this extra step. Anyone building synthesis chains or running regulatory-sensitive assays learns to take nothing at face value in these situations.

One slip-up with purity can tank an entire synthesis. Impurities, even if they make up only a small fraction of the bulk, often slide right through quality control until the error hits productivity or turns up in data inconsistency. I've dealt with this issue running organic reactions. The worst moment isn’t the impurity—it’s the time wasted tracking down freak results, only to realize the starting material was loaded with something you didn’t expect.

Industries running at scale, like pharma or agrochemicals, take contamination seriously. In these places, sample consistency translates into real money and regulatory headaches. For research, pushing for high-purity supplies means cleaning up downstream grunt work: fewer purification steps, clearer NMR spectra, and cleaner yields. There’s nothing worse than debugging a reaction protocol you’ve run a dozen times, just because a tiny impurity crept in.

Problems usually start with niche status. Not every supplier stocks N-Amylmethylamine in high purity because it doesn’t fly off shelves. Big players prioritize high-volume chemicals. Sometimes only custom syntheses or special requests offer higher-grade material, which ramps up lead times and costs. That gets frustrating if you’re running on research grant money or building a pilot plant pressuring for timelines.

Chain supply issues and storage practices throw up surprises too. A drum sitting around too long, poor sealing, or bad conditions all take a toll on quality even if purities met standards at shipment. The real world is full of cut corners here, and chemical buyers find out the hard way that not every bottle called “high purity” lives up to the name.

Pushback from customers really works. Asking for batch-specific CoAs or chromatograms turns a black box into something you can trust. For companies, keeping relationships with reputable distributors pays off over scouring the internet for one-off deals. Investing in basic spot analysis in-house (TLC, GC, HPLC) stops a lot of headaches before they start.

If the chemical keeps showing up in project after project, it pays to lock in a reliable source, and every once in a while, run your own check, even if the supplier claims everything’s perfect. After years in the lab, trusting but verifying is not just a mantra—it’s survival.

| Names | |

| Preferred IUPAC name | N-methylhexan-1-amine |

| Other names |

1-Pentylmethylamine N-Methyl-1-pentylamine |

| Pronunciation | /ɛn-ˈæmɪlˌmɛθɪl.əˌmiːn/ |

| Identifiers | |

| CAS Number | 150-76-5 |

| 3D model (JSmol) | `CNCCCCCN` |

| Beilstein Reference | 2738734 |

| ChEBI | CHEBI:51785 |

| ChEMBL | CHEMBL152798 |

| ChemSpider | 157019 |

| DrugBank | DB04115 |

| ECHA InfoCard | 100.088.071 |

| EC Number | 206-473-2 |

| Gmelin Reference | 60638 |

| KEGG | C06465 |

| MeSH | D000583 |

| PubChem CID | 12411 |

| RTECS number | AY5950000 |

| UNII | ZQN988J27A |

| UN number | UN2331 |

| CompTox Dashboard (EPA) | DTXSID80881720 |

| Properties | |

| Chemical formula | C6H15N |

| Molar mass | 87.18 g/mol |

| Appearance | Colorless to yellow liquid |

| Odor | Amine-like |

| Density | 0.767 g/mL at 25 °C |

| Solubility in water | Soluble |

| log P | 0.98 |

| Vapor pressure | 0.5 mmHg (25°C) |

| Acidity (pKa) | 10.7 |

| Basicity (pKb) | 3.36 |

| Magnetic susceptibility (χ) | -7.73×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.410 |

| Viscosity | 1.96 mPa·s (at 20 °C) |

| Dipole moment | 2.205 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 229.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -71.6 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3934 kJ/mol |

| Pharmacology | |

| ATC code | N01AX03 |

| Hazards | |

| GHS labelling | GHS02, GHS05, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Hazard statements | H226, H302, H314 |

| Precautionary statements | P210, P233, P240, P241, P242, P243, P280, P303+P361+P353, P304+P340, P305+P351+P338, P370+P378 |

| NFPA 704 (fire diamond) | 1-3-0-Alk |

| Flash point | 43 °C |

| Autoignition temperature | 280°C |

| Explosive limits | 1.2–10% |

| Lethal dose or concentration | LD50 (oral, rat): 179 mg/kg |

| LD50 (median dose) | LD50 (median dose): 179 mg/kg (mouse, intravenous) |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for N-Amylmethylamine is not specifically established by OSHA. |

| REL (Recommended) | 10 mg/m3 |

| IDLH (Immediate danger) | 100 ppm |

| Related compounds | |

| Related compounds |

N-Methylhexylamine N-Ethylpentylamine N-Propylbutylamine N-Butylpropylamine N-Heptylmethylamine |