Hexylamine's story doesn’t show up in most mainstream chemistry textbooks. Still, its background helps paint a fuller picture of modern organic chemistry’s evolution. Early chemists probably ran across it while tinkering with aliphatic amines, and for most of the 20th century, it stayed mostly off the radar, overshadowed by relatives like ethylamine and butylamine. Yet, hexylamine’s role grew with the expansion of industries using surfactants, corrosion inhibitors, and antibiotics, feeding the growing demand for specialty amines. More companies started synthesizing it on a larger scale, prompted by needs within agriculture, rubber, and pharmaceuticals. The development of higher-pressure catalytic hydrogenation in the mid-century helped move hexylamine from an obscure lab oddity to a regular on order lists worldwide.

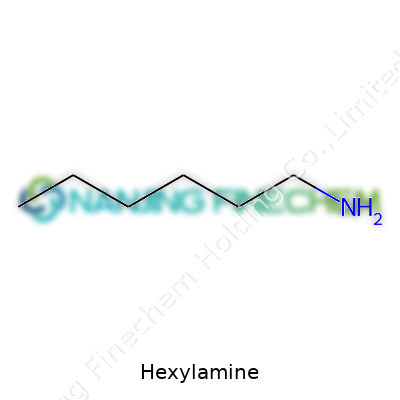

Hexylamine lands on the shelf as a six-carbon, straight-chain aliphatic primary amine, molecular formula C6H15N. The stuff smells strong—kind of like fish and ammonia had a really long day together. It serves as a building block for other chemicals, helping shape water treatment additives, pesticides, and textile softeners. Its chain structure gives it moderate hydrophobicity, so it finds work as a stabilizer or intermediate in processes where shorter or branched amines just don’t cut it.

Open a bottle in the lab and it’s hard to ignore—the odor will stick with you for hours. Hexylamine is clear and colorless in its pure form, but it picks up color over time, especially if stored poorly. Its boiling point, just shy of 131°C, puts it well above many common solvents, but it still evaporates quickly, especially in open spaces. Solubility falls between water and basic hydrocarbons; mix it into water and a chunk dissolves but don’t expect miracles without a little heat and stirring. Its amine functionality means it grabs protons in acidic settings and forms salts, making it useful for tweaking pH or building other nitrogen-containing compounds.

Suppliers put out hexylamine in steel drums or high-density plastics, careful to label hazards tied to strong bases, moisture sensitivity, and serious toxicity. The most common concentration in trade is above 99%, giving chemists some flexibility. Labels spell out "n-Hexylamine," and Technical Data Sheets line up CAS Number 111-26-2. Purity, water content, and color (using APHA or Pt/Co grading) appear, and producers remind buyers to avoid mixing with acids or strong oxidants outside controlled setups.

Modern manufacturers use catalytic hydrogenation of hexanenitrile or hexanal oxime. Pressurized hydrogen, nickel or cobalt catalysts, and heat crank out hexylamine in reactors built for safety and efficiency, not trial-and-error. After hydrogenation, distillation isolates the product and strips out water and light ends. Some routes start with natural fats or oils, where fatty acids get converted to amines by treatment with ammonia. Decades ago, less efficient processes and purification led to more byproducts and inconsistent purity—now, continual improvements in catalysts and process monitoring help keep things tightly controlled.

In the lab, hexylamine acts like a typical primary amine. It reacts eagerly with acids to form salts, and you’ll spot it making amides or ureas by combining with acid chlorides or isocyanates. Attach it to ethyl acrylate, and the result is a β-amino ester that finds its way into coatings and adhesives. When subjected to alkylation, the nitrogen side handles further substitutions, yielding a range of secondary and tertiary amine products for tailored uses. Hexylamine often shows up in modification steps for polymers, where its long enough chain adds both flexibility and hydrophobicity.

Order sheets and safety documentation reveal several names—n-Hexylamine, aminocaproic hexane, and 1-aminohexane. European and Asian trade names might read "Hexamin," while some older literature will call it "Hexylamine, straight-chain." CAS registry sticks with 111-26-2 across the board. Confusion pops up as branched isomers (like isohexylamine) sometimes sneak into discussions, but technical use sticks tight to the straight-chain version.

Even seasoned chemists take care with hexylamine. Its strong odor isn’t just unpleasant—exposure triggers intense mucous membrane irritation, coughing, and headaches. Skin contact causes burns and redness, and inhalation risks stick, especially in poorly ventilated shops or factories. Workers must wear gloves and goggles, and exhaust fans keep vapors from pooling. Spills get neutralized immediately with dilute acids, and waste streams run through proper chemical disposal pipelines. Storage tanks require ventilation, sturdy seals, and pressure reliefs, given hexylamine’s volatility and reactivity with CO2 in the air. Training programs hammer home emergency procedures and safe handling, which help keep accident rates down.

Hexylamine reaches into a surprising array of industries. In water treatment, it neutralizes corrosive acids, forming salts that don’t build up scale in pipes. The agricultural sector uses derivatives for pest control, and rubber processing benefits from antioxidants built with hexylamine. Textile plants tap it for softeners and antistatic agents, while paints and coatings use specialized amides for improved adhesion and flexibility. Pharmaceutical research checks its derivatives for antimicrobial properties, and refineries use it as a corrosion inhibitor in gas streams. Every few years, new patents surface for blends in lubricants, fuel additives, and polymer stabilizers.

Academic labs look for new uses of hexylamine as a building block in green chemistry projects. Genetic engineering companies experiment with modified versions in protein sequencing and microencapsulation, and battery manufacturers investigate it as a potential electrolyte modifier. The search for more sustainable processes places focus on renewable sources—can hexylamine be made from bio-based hexanenitrile? Several funded projects take up this challenge. Emerging research from Asia looks to harness its chain length for next-gen surfactants better suited to altered oil-water interfaces.

Decades of animal studies and workplace monitoring place hexylamine in the toxic irritant category. Acute exposure brings on headaches, nausea, chest discomfort, and heavy eye watering. Workers with repeated exposure sometimes show skin sensitization, so safety officers frown on regular contact. Oral toxicity studies in rodents show moderate LD50 values, and chronic studies suggest some risk for respiratory tract injury at higher doses. Regulatory agencies like OSHA and the European Chemicals Agency demand detailed risk assessments, and companies must show effective fume control in production areas. Wastewater treatment also limits hexylamine content, due to its toxicity to aquatic life.

In the next decade, hexylamine’s profile may rise as niche industries ask for specialty amines with a mix of chain length and reactivity. The age of green chemistry could favor bio-derived aliphatic amines, pushing producers toward fermentation or catalytic processes using renewable feedstocks. More stringent safety regulations likely will influence how companies store, ship, and monitor air and water emissions. New research in medicine and electronics seeks out longer-chain amines for targeted drug delivery or battery additives, so demand could move beyond traditional chemical manufacturing. If renewable chemistry can reduce the carbon footprint of production, hexylamine may find an even wider array of uses, cementing its reputation as a workhorse in more than just behind-the-scenes applications.

Hexylamine doesn’t make front-page headlines. In fact, you might walk through your whole life without once thinking about it—unless you tinker with chemicals or work in a factory where some sharp smells linger in the air. Still, products like hexylamine sit behind a lot of things many folks rely on, and its story shows how the backbone of chemical manufacturing shapes more than just white lab coats and diagrams.

I’ve had my share of muddy boots and garden failures. Fertilizer compounds make a big difference between green lawns and sad patches of dust. Hexylamine shows up in agricultural chemicals, lending itself as a building block to fungicides, herbicides, and even as an ingredient in some pesticides. Crops catch fewer diseases. Yields inch up. That means more wheat and less crop loss in a world where food security isn't just an academic issue.

Move over to cleaning, especially heavy-duty industrial varieties, and hexylamine steps in again. It acts as a corrosion inhibitor, making sure pipelines and machinery don’t rust out and quit early. From water treatment facilities to the insides of laundry machines, long service life saves money. Less maintenance usually means lower costs down the road and—maybe just as important—a smaller pile of broken equipment heading for the scrap yard.

Back when I worked in a warehouse, the smell of motor oil and chemicals pretty much lined every shift. Additives give oil and lubricants longer legs. Hexylamine goes into formulations to prevent metal surfaces from grinding themselves down. Machine parts last longer, and downtime drops. The trickle-down effect matters for anyone who drives a car, rides a bus, or counts on a tractor to plow a field. The less stuff breaks, the smoother everything runs, which keeps bigger systems moving.

Pharmaceuticals use building blocks like hexylamine to stitch together certain types of drugs. The process feels hidden, but this ingredient often plays a role far upstream in manufacturing, shaping the molecules doctors count on. Adding hexylamine might not sound glamorous, but removing bottlenecks or inefficiencies at these basic steps can ripple through the entire system, improving access or price for end users.

Any chemical with industrial uses stirs up questions around safety. Some workers handle strong-smelling chemicals with heavy gloves and face shields for a reason. Exposure can irritate skin or eyes; mismanagement can introduce risk to waterways or the wider environment. Factories that use hexylamine must invest in training, safety gear, and proper ventilation. The push for greener, safer alternatives starts in places like this, where efficiency, health, and environmental issues overlap.

Moving forward, attention must focus on tightening protocols, scaling up recycling systems, or developing safer substitutes when possible. Open dialogues between workers, communities, and regulators can help iron out problems early. We all share the downstream benefits—from cleaner water to safer workplaces—when these conversations turn into action.

Hexylamine has a sharp, fish-like odor, and if you've ever handled it, you know that the smell isn’t easy to forget. This chemical pops up in laboratories and some production lines. Most folks don’t realize how quickly trouble can start if you get careless. Breathing in the vapors can bother your nose and lungs. If the liquid gets on your skin or in your eyes, you’ll feel a burning sting. Working around it, you start to pick up habits that keep your day from going south.

No one likes wearing thick gloves or face shields in a warm lab, but skipping the gear isn’t worth the risk. Nitrile or neoprene gloves protect your skin from splashes. Safety glasses or goggles keep your eyes safe—because nothing ruins your day like chemical burns. Throw on a long-sleeved lab coat, and zip it up. If the job kicks up fumes, slip on a fitted respirator. Walk by a project during cleanup and you’ll catch that smell—so make sure the room is vented well enough to clear it out.

It’s tempting to open a bottle at your bench and work through a task, but air movement is your best friend. A ducted fume hood pulls away any stray vapor. I’ve met folks who say a cracked window or fan is enough, but it’s not—fume hoods get built for this kind of work. Store hexylamine in a cool spot, since temperature swings build pressure in sealed bottles. Keep containers tightly closed and far from acids or oxidizers. Labels should stand out—never trust a faded sticker when it comes to stuff like this.

Spills always happen faster than people think. I’ve seen a bottle knocked over in a shared lab and everyone froze, not sure what to grab first. You need spill kits ready and easy to find. These should include absorbent pads, gloves, and bags for waste. If the liquid hits your skin, get under running water right away and rinse for 15 minutes—don’t try to wipe it off first. For eye exposure, use the eyewash station, and don’t cut your rinse short; even a few seconds make a difference.

Fire is another worry. Hexylamine catches easily and burns with invisible flames. Small amounts on a benchtop can flare up if you’re not paying attention. Fire extinguishers rated for chemical fires belong nearby. Smelling a strong fishy odor means it’s time to step out and let the airflow clear the room before returning.

Working with hexylamine never feels routine, even if you’ve done it for years. The simple habits—labeling bottles, double-checking the fan, replacing leaky gloves—matter more than any fancy procedures posted on a wall. Small shortcuts can cause a chain reaction of problems. Some folks find safety talk tedious, but nearly everyone learns the hard way at least once. Being thorough, preparing for headaches before they land, and respecting these chemicals day after day keeps everyone safe to work another shift.

Hexylamine always makes me think of the many hidden players out there in the world of industrial chemistry. You rarely hear about it at a backyard barbecue, but this compound helps do a lot of heavy lifting behind the scenes. Hexylamine’s chemical formula is C6H15N. It stands for six carbon atoms, fifteen hydrogens, with one nitrogen tacked on at the end. Draw it out and you get a straight line of six carbons, with the nitrogen sitting on one end, often written as CH3(CH2)5NH2.

The structure looks deceptively simple: a chain that starts with a methyl group and runs through five methylenes, capped off at the far end with an amine group. If you’ve ever handled amines, you know that recognizable ammonia smell. Hexylamine picks up that trait—one whiff, and it’s clear you’re nowhere near a flower shop.

People don’t tend to stop and appreciate how many products rely on things like hexylamine. It plays a supporting role in making pharmaceuticals, rubber chemicals, corrosion inhibitors, pesticides, and surfactants. In the pharmaceutical world, a lot of chemical synthesis needs simple amines because their nitrogen group can swap around and create new bonds. I remember talking with a chemist friend who pointed out how often small molecules like this drive reactions forward in the lab—like silent partners, getting little recognition outside a safety data sheet.

Big tanks of it also show up in water treatment plants and oil refineries. Hexylamine helps keep corrosion at bay in pipelines, so companies don’t lose millions to rusty pipes and leaking joints. That use rarely gets a spotlight, but it shows how chemistry keeps our infrastructure going quietly in the background. A leaky water main in my old town helped me appreciate how much effort sits behind keeping things flowing without a hitch.

I’ve seen what happens when safety gets tossed aside for speed, and hexylamine isn’t something to brush off. Exposure brings skin, eye, and respiratory irritation. The compound’s strong, fishy odor is more a warning than a discomfort. Gloves, goggles, and good ventilation aren’t optional. No one should treat hexylamine as a walk in the park—trust me, there’s no heroism in making a risky shortcut with chemicals that can burn and irritate this much.

Like a lot of amines, hexylamine can harm aquatic life if dumped into waterways. With increased awareness about environmental safety, industries have started looking for options that break down faster or cause less harm. More and more companies take the route of closed-loop systems and on-site waste treatment. I know people who run plants where they recycle solvents and catch toxic vapors long before they head for a river or stream. That extra attention makes a real difference—not just for the people handling the chemical, but for everyone downstream.

I always root for solutions that treat both workers and natural resources with respect. Good training, tough personal protective gear, and simple fixes like better ventilation go a long way. Engineers continue to hunt for syntheses that use less hexylamine, or switch in greener chemicals whenever possible. Incentives for cleaner processes and tougher checks on industrial waste force the question: How can we keep the boat afloat without tipping it over?

The lesson I’ve picked up, after years around chemical plants, is this: every bottle on a shelf tells a bigger story. Hexylamine might have a plain name and simple formula, but its impact—good or bad—depends on the choices people make at every step.

People often overlook chemicals after ordering them. You picture hexylamine as just another liquid on the shelf. Then an unexpected splash, strange odor, or label warning jolts you back to reality. My first real lesson came watching a small company shuffle fifty-gallon drums into a back corner, lid slightly ajar, next to cleaning supplies and paint cans. No one got hurt, but a strange smell lingered for weeks. Hexylamine releases fumes fast if you get careless. Safety posters rarely capture how quickly a bad storage decision leads to trouble.

Hexylamine brings two big challenges: it’s flammable and creates strong, fishy vapors that act as eye and nose irritants. A stuffy storeroom without proper ventilation, or a cracked seal on a drum, turns a simple storage mistake into a problem for anyone unlucky enough to walk by. Many workers ignore the chemical’s warning labels because they're focused on bigger hazards, like acids or high voltage. Yet, a good whiff of hexylamine makes you realize just how harsh a “minor” chemical can get.

I’ve seen what happens when barrels sit too close to heat lamps, water pipes, or even windows on a sunny day. Hexylamine breaks down or even catches fire at lower temperatures than most people expect—overheated rooms and direct sunlight raise this risk. Leaky drums sometimes end up in corners near electrical panels. That increases the danger tenfold. Firefighters hate surprises, and hexylamine fumes can provide one.

Smart storage skips expensive gizmos and focuses on space and consistency. Keep hexylamine in a cool, dry, well-ventilated spot, away from open flames, heaters, and direct sunlight. Shelves or racks made of metal resist leaks or drips better than old plywood. Leave enough room for air to move. It might look wasteful to someone paying rent by the square foot, but that space keeps fumes from building up. If the room has windows, install blackout shades or UV film to cut down on sunlight exposure.

The right container makes all the difference with chemicals like this. Manufacturers usually sell hexylamine in thick, airtight drums or bottles lined with corrosion-resistant material. Don’t swap containers unless there’s no other choice. Markings and labels look boring, but they’re your friend. Never trust a mystery drum. A clear “HEXLYAMINE—FLAMMABLE, IRRITANT” sticker stands out when you need it.

The people in charge need a plan for leaks and spills. That means keeping absorbent material, baking soda, or sand nearby. Even small leaks can stink up a building. If someone spills hexylamine, open a window or use a fan to push those fumes outside. Never mop it up with water—the chemical floats and spreads faster than you expect. Emergency showers and eyewash stations near the storage site let workers deal with any splash or spill quickly.

Personal experience says: never cut corners with chemical safety. Hexylamine doesn’t attract attention like sulfuric acid or gasoline, but that makes mistakes easier. Rotate stock so old materials never sit for years, and stick to the basics: cool, dry, ventilated, labeled, secured. Repeat checks, ask questions, and plan for the rare event. Most trouble comes from routine turning into carelessness, and with hexylamine, that’s a shortcut to real risk.

Pick up a bottle of hexylamine, and you’ll pick up more than just weight. This liquid gives off a strong, unmistakably fishy smell—strong enough to turn heads. It’s colorless, but don’t let that fool you into thinking it’s harmless water. Hexylamine brings an oily feel. If you’ve ever accidentally spilled amine-based chemicals in a lab, you know how stubborn that slick texture sticks on your skin or surfaces. This oiliness comes from its chemical structure: a fairly simple chain of six carbons with an amine group at one end. Sometimes, a chemical’s feel in your hand or its aroma can tell you as much as a page of numbers.

Getting a little warmer, you reach hexylamine’s boiling point—not much above what you’d see with water, but still different. Hexylamine boils at about 131 degrees Celsius, making it easy to distill or evaporate in most lab setups. Unlike sticky tar chemicals or high-boiling oils, this one moves up into the air with just a bit of heat. When it comes to freezing, hexylamine turns solid around -52 degrees Celsius, which means it freely flows as a liquid at anything close to room temperature. This temperature flexibility makes it useful when formulating chemicals that need to stay liquid longer—nobody wants to fight stubborn clogs or gels in pipes or tanks.

Hexylamine stands out for its mixability. It blends very well with alcohols and ethers. Pour some into water, and it dissolves, but not as eagerly as short-chain amines like methylamine. The longer alkyl chain pulls it back a bit; you see layers start to separate at higher concentrations. In solvents like benzene or chloroform, though, hexylamine dissolves without a fuss. In my experience, this makes it a handy tool for cleaning or removing substances in organic labs—just don’t expect one hundred percent cooperation in water-heavy mixes.

Density might sound like a dry detail, but in a chemical facility it spells balance. Hexylamine comes in at around 0.77 grams per cubic centimeter, a bit lighter than water. Pour it in a beaker, and it floats up on top. This lighter-than-water property makes working with hexylamine tricky: leaks can run across the surface of a spill containment pool rather than mixing in. On one hand, it cleans up faster; on the other, it can sneak away to unwanted places if you’re not careful. Sometimes you only appreciate the importance of density after chasing a spill through a crowded bench top.

Coming into direct contact burns skin and stings eyes. It absorbs into the body through the skin faster than most people expect. Wearing gloves sounds basic, yet it’s easy to skip protection when you’re in a hurry or distracted. The chemical’s vapors can cause headaches or breathing irritation. Even when you think the space is well-ventilated, smells linger. Using fume hoods or open air isn’t an extra step—it's the difference between a safe day and an emergency.

For all its quirks, hexylamine keeps finding its way into production lines—cleaning agents, pharmaceuticals, and corrosion inhibitors. Safe storage matters: tightly sealed containers, stored cool and away from anything acidic. The risk of fire jumps if storage gets sloppy, as it flashes at a temperature just below room temperature. Routine checks and proper training protect both the workers and the products. Over the years, talking shop with colleagues, it’s always the properties like smell, volatility, and density that show up as real-world challenges—not just numbers in a data sheet.

| Names | |

| Preferred IUPAC name | Hexan-1-amine |

| Other names |

1-Aminohexane Hexylamin n-Hexylamine Aminohexane |

| Pronunciation | /ˈhɛksɪl.əˌmiːn/ |

| Identifiers | |

| CAS Number | 111-26-2 |

| Beilstein Reference | 633873 |

| ChEBI | CHEBI:4260 |

| ChEMBL | CHEMBL15610 |

| ChemSpider | 7271 |

| DrugBank | DB03572 |

| ECHA InfoCard | 100.005.367 |

| EC Number | 203-852-3 |

| Gmelin Reference | 6719 |

| KEGG | C01877 |

| MeSH | D06BB5GH4K |

| PubChem CID | 8103 |

| RTECS number | MN0175000 |

| UNII | 87GH8I3A5X |

| UN number | UN2733 |

| Properties | |

| Chemical formula | C6H15N |

| Molar mass | 101.19 g/mol |

| Appearance | Colorless to yellowish liquid with an ammonia-like odor |

| Odor | Ammonia-like |

| Density | 0.766 g/cm³ |

| Solubility in water | miscible |

| log P | 1.96 |

| Vapor pressure | 5 mmHg (20 °C) |

| Acidity (pKa) | 10.56 |

| Basicity (pKb) | 3.37 |

| Magnetic susceptibility (χ) | -6.2e-6 |

| Refractive index (nD) | 1.417 |

| Viscosity | 9.5 mPa·s (at 20 °C) |

| Dipole moment | 0.648 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 254.8 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -111.6 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -4158.7 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS05, GHS06, GHS07 |

| Pictograms | GHS02,GHS06 |

| Signal word | Danger |

| Hazard statements | H302, H311, H314, H317, H332 |

| Precautionary statements | H302, H312, H314, H332 |

| NFPA 704 (fire diamond) | 2-3-1 |

| Flash point | 41 °C (106 °F) |

| Autoignition temperature | 285 °C |

| Explosive limits | 1.2–7% |

| Lethal dose or concentration | LD50 oral rat 350 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral (rat) 285 mg/kg |

| NIOSH | UN1185 |

| PEL (Permissible) | 5 ppm |

| REL (Recommended) | 5 ppm |

| IDLH (Immediate danger) | 100 ppm |

| Related compounds | |

| Related compounds |

Pentylamine Heptylamine Octylamine Butylamine Propylamine |