Back in the mid-19th century, researchers working with ammonia derivatives stumbled across a curious-smelling liquid in their glassware—this was dimethylamine. Early chemists treated it as a laboratory curiosity, then the growing need for synthetic dyes, rubber, and pharmaceuticals shone a spotlight on small amines. The appetite for chemical manufacturing in the 20th century made dimethylamine downright common in factories across Europe and North America. Engineers and scientists experimented, swapped notes, and scaled up production as more sectors discovered its potential. This drive for practical uses and industrial growth pushed understanding and output far beyond bench experiments, embedding dimethylamine into the backbone of modern chemistry.

Dimethylamine comes as a colorless, pungent gas or liquid depending on temperature and pressure. Its formula, (CH₃)₂NH, keeps things small and nimble, making it easy to blend with water or combine with many organic compounds. Bulk distribution often relies on storing it as a solution in water, which tames its volatility and eases handling in plants. Chemical supply catalogs list it alongside building blocks for drugs, pesticides, dyes, rubber goods, and even fuel additives. Demand on the international market keeps pushing producers for more volume, purer grades, and better logistics as industries want reliability and quick turnaround.

Logs of safety data sheets mention its sharp, ammonia-like odor and boiling point at around 7°C, barely above freezing. Keep it under pressure and you get a liquid, but in open air, it shoots up as a vapor. It clings eagerly to water, dissolving with a hiss and pumping up pH, so even a small spill can fill a room with an overwhelming smell unless ventilated. High reactivity due to that nitrogen center lets it act as both a base and a nucleophile—handy for synthesizing everything from surfactants to herbicides. Flammable and hazardous in concentrated form, it still turns up safely enough in plenty of daily-use products after further chemical transformations.

Suppliers keep tight watch on the minimum purity—most industrial applications ask for 40% aqueous solutions, with gas-phase needs often demanding 99% or higher. Labels stipulate hazard pictograms, point to the need for protective gear, and highlight storage warnings. Everything ships under strict codes: cylinder valves need corrosion resistance, drum markings must display United Nations numbers, and transport must follow international hazardous goods regulations. Operators look for product certificates from batch analysis, including water content, trace amines, and any potentially toxic byproducts.

Anyone who’s taken a class in industrial chemistry remembers seeing methyl chloride (or even methanol) bubbled over ammonia, catalyzed by a little metal or basic alumina. This synthesis spits out a mix of methylated amines, so the next challenge is separating dimethylamine from mono- and trimethylamine. Fractional distillation gets the job done in many plants, with tweaks depending on the scale and access to cheap raw feedstocks. Newer methods tinker with catalysts and reactor design to avoid waste and cut down energy use as environmental rules tighten.

The two methyl groups and the lone nitrogen let chemists run all sorts of reactions. Dimethylamine reacts quickly with acids to form salts—dimethylammonium chloride shows up in pharmaceuticals and cleaning agents. It combines with carbon disulfide in production lines for rubber accelerators and slips into alkylation or nitrosation reactions to build more complex molecules. Its flexibility means researchers squeeze value from both simple derivative chemistry and more ambitious synthetic pathways, often chasing patent angles or fine-tuning specialty materials for new products.

Not everyone calls it by the same handle. Chemical literature and trade usage might say N,N-Dimethylamine, DMA, or even just "dimethyl amine" split into three words. Its salts pick up names like dimethylammonium chloride or N,N-dimethylammonium nitrate. Specific brands run from generic "DMA solution" to labeled mixtures for certain industries. Knowing alternate names helps cut through confusion on safety sheets, shipping manifests, and market research, especially as translations bounce from Chinese to German to English.

Facilities moving dimethylamine need plans for leaks, exposure, and spills. Inhalation can irritate lungs and eyes, so good ventilation and personal protection rank at the top of every handling sheet. On storage, engineers keep tanks cool and pressurized, far from oxidants or fire sources—any slip can mean rapid expansion and dangerous releases. Regular training, emergency drills, and monitoring equipment stay on every plant manager’s checklist. International rules, including OSHA and REACH, spell out exposure limits and safe work practices, forcing compliance from production to shipping to end-use.

Anyone digging into product origins might be surprised how often dimethylamine turns up behind the scenes. Rubber factories lean on it for vulcanization accelerators, giving car tires and seals their spring. Farming industries use its derivatives in herbicides and fungicides, helping boost crop yields. Pharmaceutical labs draw on it for local anesthetics, antihistamines, and painkillers. Even in wastewater treatment, DMA-based chemistries snap up pollutants or bust biofilms. Every industry looks for reliability and performance, and the quick chemistry of dimethylamine offers ways to shave time, cost, or energy from core processes.

Universities and corporate labs still poke at the edges of what dimethylamine can deliver. Environmental chemists try to design “greener” syntheses with reduced emissions or improved atom economy, narrowing byproducts that once polluted air or water. Pharma screening programs chase new routes to active compounds, using dimethylamine as a basic, low-cost building block. Polymer researchers experiment with modified resins and specialty plastics, hoping for better durability or chemical resistance. All this lab work means new patents, process improvements, and sometimes even serendipitous discoveries nobody expected.

Occupational health studies track effects of big exposures—irritation to respiratory tract, skin burns with concentrated splashes, and worries about long-term impacts. Dimethylamine ranks as hazardous in concentrated forms, pushing cleanup protocols and air monitoring right to the top in any facility handling tonnage. Toxicity studies also follow environmental breakdown—how long it lingers if spilled, the products it forms, and what that means for ecosystems. Regulators regularly update guidelines as new research emerges, and companies invest in testing and mitigation to reduce risks at every step from lab to end user.

With new regulations reshaping chemical manufacturing, high hopes ride on greener and smarter methods for both producing and using dimethylamine. Rising demand for custom molecules in pharma and agri-business spurs process innovation, while the push for sustainable, low-waste manufacturing opens the door to alternative feedstocks and biocatalysts. Advances in plant design, real-time monitoring, and digital supply chains help cut costs and slash hazards. As the world keeps searching for solutions to environmental and supply chain pressures, the role of nimble, versatile chemicals like dimethylamine only looks set to grow—so long as science and safety keep pace with demand.

Dimethylamine doesn't sound catchy. Few people talk about it at cookouts or see it on news headlines. Yet, it's behind a lot of things we touch and rely on day to day. It's one of those chemicals that, quietly, powers elements of modern life.

If you’ve ever noticed crops standing tall against weeds, dimethylamine plays a hand. Farmers use herbicides based on this compound to keep weeds in check without trashing the fields. I come from a family with farming roots, and every spring, we watch fields being treated to battle weeds that could wipe out a season’s earnings. Dimethylamine salt-based herbicides keep yields strong by taking down wild growth that competes with crops.

Mixing science into agriculture isn’t just about convenience. Weeds left alone can hurt food supplies, push up prices, and threaten a small farmer’s survival. Reliable weed control helps keep grocery stores stocked and food prices more stable.

While nobody likes thinking about chemicals in medicine, a lot of the painkillers and cold remedies that fill our cabinets depend on synthetic processes. Dimethylamine steps in as a building block. Chemists use it to stitch together pharmaceuticals, making drugs for heart issues, allergies, infections, and more.

Think of its role as being like flour in baking. You don't often notice the flour, but you can't get bread or cookies without it. Without dimethylamine, it gets tougher, slower, and more expensive to bring both everyday and life-saving medicines to patients.

Take a walk through your kitchen or garage, and you’ll spot dimethylamine’s fingerprint. It’s in the cleaning products you use to wipe down counters and scrub bathrooms. Even the soaps that keep hands clean use ingredients made from it.

Then there’s rubber. If you like smooth car rides, dimethylamine is part of the process that shapes the tires. It helps make rubber strong, springy, and ready for a beating on the road. Not using it would bump up production costs or change performance standards, and, for anyone who likes traveling safely, that’s not a trade worth making.

Factories use dimethylamine to make solvents and resins. This happens at massive scales. When I toured a chemical plant years ago, safety officers hammered home how vigilant workers must be. This chemical vapor carries a single whiff that smacks of ammonia and can irritate the eyes and lungs fast.

There's a flip side: any leak or spill can be hazardous. Proper storage, use of protective gear, and smart engineering can keep risks managed. Big factories and local transport companies must watch operations closely—one slip could put both workers and nearby communities at risk.

Right now, regulation and oversight go a long way. Regular drills and air monitoring help, but nothing replaces staff who take training seriously. That said, safety shouldn’t cost jobs or put small businesses on the edge. Sharing best practices, federal grant programs, and portable detection tech could help level the playing field.

Dimethylamine is a reminder that chemistry shapes daily life, for better and sometimes for worse. How we manage it says a lot about the future we want.

Dimethylamine tends to catch people off guard. In a busy lab or industrial site, all it takes is one person forgetting their mask, and the sharp, ammoniacal smell hits the air fast. Years back, I spent a summer at a small chemical processing plant. We handled a lot of dimethylamine in big drums. Some of the younger workers didn’t realize how quickly symptoms pile up — throat burning, watering eyes, pounding headache. It isn’t dramatic, like sulfuric acid burns, but it sneaks up. That taught me: nobody gets a pass on following real-world safety basics here.

Gloves matter. Not thin latex ones—nitrile or heavy-duty rubber. It’s easy to forget, since people think skin contact just means irritation, but frequent exposure soaks right in. Full goggles beat safety glasses every time. A face shield keeps splash-back out of mouths and noses. Respirators should be standard in closed spaces. Dimethylamine vapor doesn’t need much to leave lungs feeling raw. Cartridge respirators with organic vapor filters make a difference. The one coworker who skipped his for “just five minutes” regretted it quickly.

I once saw a senior tech loan his spare goggles to a new guy, just so nobody had to sit out that shift. Good call. Loan gear if you notice gaps — pride won’t keep you healthy.

Some shops think a cracked window or old vent fan counts as protection. From experience, that’s a shortcut to trouble. Forced ventilation, exhaust hoods, and negative pressure setups cut down vapor build-up. I remember working nights in a makeshift setup where vents rattled too much to use. By morning, you couldn’t ignore the low-level nausea anymore. Investing in solid airflow saves headaches, literally.

Dimethylamine likes to leak. Gaskets go brittle, valves stick, and pretty soon there’s a puddle where none should be. Keep drums upright, anchor them so nothing tips. Clearly labeled areas keep confusion low. If people store acids nearby, accidents wait to happen—dimethylamine reacts, forms toxic gases, or even catches fire. Practice personal checks before moving containers. Even a quick look for swelling or a corroded lid pays off.

A few spills happened on my watch. No single worker should ever try solo cleanup. Alert the team, pull in backup, use the proper neutralizer—often a weak acid like vinegar—then contain with absorbent pads. Throw out whatever clothing catches more than a splash; washing doesn’t always cut it. Keep eyewash and emergency showers close. I once rushed a friend to the eyewash station. Even one splash can set back recovery for weeks.

Regular safety talks bore people, but every real-world accident starts with “just this once.” Practical, hands-on training beats old handouts. Run through drills—where’s the nearest shower, which filter for this mask, who knows which drum holds what? People remember what they do, not what they’re told once.

Sometimes a substitute chemical can do the same job with less risk. Chatting with a peer at a bigger facility opened my eyes to newer, lower-vapor compounds. The switch took some paperwork, but incidents dropped. If dimethylamine use can’t be avoided, culture matters more than rules. Look out for each other, drop ego at the door, and never let routine dull your sense of danger.

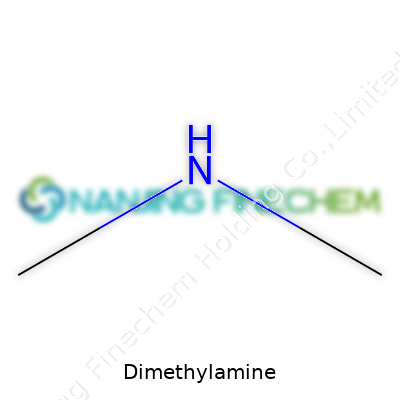

People often ask for chemical formulas and then tune out after hearing “C2H7N”. That’s the formula for dimethylamine. But behind those letters and numbers, there’s a tiny molecule with two methyl groups (that’s CH3 for folks who remember high school chemistry) attached to something called an amine group. In real life, the structure looks like this: imagine a nitrogen atom holding onto two “arms” made of CH3 and a third, shorter arm with a hydrogen. It’s written as (CH3)2NH, which really spells out who’s hanging around in this group.

Some folks walk past the topic thinking it’s only for folks in a lab coat, but this compound shows up in the background of things we use every day. It floats through the process of making medicines, shows up in fertilizers that get sprinkled across fields, and even helps whip up some cleaning products. So you can imagine, if something affects how dimethylamine is handled or shows up in the news, it has ripple effects hitting everything from the food on a dinner plate to products stashed under the sink.

The way those carbon, hydrogen, and nitrogen atoms lock together gives dimethylamine its sharp smell—some say it brings to mind rotting fish or old ammonia. That’s not just a quirky fact; it warns workers to handle it carefully. Dimethylamine boils at only 7°C (about 45°F), so just sitting at room temperature, it’s ready to leap off as a gas. Any storage or transport needs tight seals and good ventilation.

From experience, I remember seeing barrels labeled with pink and black stripes, cautioning us not to let the fumes linger indoors. That’s not just paperwork paranoia. Dimethylamine can irritate lungs, eyes, and skin in big whiffs. So folks running factories or mixing chemicals owe it to their teams to keep air moving and check for leaks.

Most of the dimethylamine shipped around gets used quickly as a building block. It’s not hanging around warehouses for long, because companies want to turn it into herbicides or solvents. That puts pressure on rigid schedules and planning, since letting a temperature-controlled tank slip could mean a safety problem or a costly disaster.

I’ve watched teams debate whether to invest in thicker storage tanks or better alarm systems. Real investment doesn’t only save money; it safeguards lives and keeps the supply chain humming. According to the National Institute for Occupational Safety and Health (NIOSH), even a short-term exposure at 10 ppm in the air is the recommended max. Strict limits mean plant managers and drivers always juggle between rushing orders and standing firm on safety.

There’s room for improvement—smarter engineering controls, wearable tech to watch the air, and community awareness. Anyone living near chemical plants needs straightforward answers about what’s getting cooked up nearby. Outreach beats cover-up, especially for compounds that escape as gases. Companies owe those answers to their workers, neighbors, and customers, not only regulators.

In the end, chemistry touches more lives than most realize. Dimethylamine is just one example of a small compound powering bigger things, from growing food to making medicines. Awareness and straight talk about handling, safety, and transparency really do shape healthier outcomes for everybody in the chain.

Walk into any industrial facility tinkering with solvents or specialty chemicals, and you’ll probably spot barrels of dimethylamine somewhere along the supply chain. Chemists count on it for making everything from pharmaceuticals to pesticides. This stuff—unstable, pungent, and as volatile as an open can of gasoline—demands respect. Handling mistakes rarely end quietly. At my old job, just a tiny leak could empty out a warehouse floor when the smell started creeping. It sticks with you.

Dimethylamine won’t last in any leaky container. In most setups, storage happens under pressure--in drums, cylinders, or tanks built for the task. Stainless steel wins on that front; other metals rust through or react badly with the stuff. No one wants corroded tanks in their yard. Keeping it cool goes a long way, too. Stored in the open on a hot summer day, vapors find their way out fast. You get pressure spikes or the pop of a blown valve. Cold storage, good insulation, and shade cut down that risk.

No manager wants to see the hazmat crew running toward their plant gate. Even a small leak of dimethylamine turns into alarms, rushed evacuations, and angry neighbors. Vapors irritate eyes and lungs in seconds. High concentrations are plain toxic. Monitoring tools save lives but only if people actually use them. Some firms get lazy, thinking “we checked last year, it’s fine.” Then a fitting fails, and chaos takes over.

Beyond the health scares, dimethylamine loves to burn if it catches a spark. Flammable limits hover low. That means a stray static charge or sloppy welding job starts a blaze that water can’t put out. Firefighters don’t want a call here. The right fire suppression systems, well-labeled shut-off valves, and regular system tests keep the odds in your favor.

Truck drivers know the drill—double-check your paperwork and make sure every label matches. Once, I watched a crew confuse two tanks. It nearly sent the wrong chemical cross-country. That close call ended with stronger checklists and extra safety locks on valves. Road transport rules look strict for a reason. DOT regulations spell out what gets loaded, how much, and in which kind of container. Tankers come pressurized and reinforced for good reason: Dimethylamine does not belong in a rickety truck with a tarpaulin roof.

Trained eyes spot problems before disaster. Drivers check for frost on fittings, test pressure relief valves, and look under the frame for leaks before driving away. Carriers with good reputations don’t skimp on training. One slip—someone lights up a cigarette next to a vent pipe, or skips a safety check—and the margin for error disappears.

Smart teams insist on eye wash stations and emergency shutoffs close to storage tanks. They swap out gaskets before a crack appears, not after. Some plants bring in third-party inspectors once a quarter to check seals and pressure gauges. Others use remote sensors that flag tiny leaks before anything turns ugly. Updated safety sheets and real-time alerts mean even new hires know what to do if alarms sound off.

Everyone in the supply chain, from the chemist to the truck driver, plays a part in keeping storage and transport safe. The stuff isn’t forgiving—treating it with care never goes out of style.

Dimethylamine gets tossed around a lot in chemical plants, labs, and places that make dyes or herbicides. In its pure form, this stuff is a colorless gas with a fishy smell you won’t soon forget. Breathing it in, getting it on your skin, even splashing some in your eyes—none of those are small problems. Most people never cross paths with it, but workers who do ought to respect how quickly it can knock things sideways.

The danger kicks in fast. Dimethylamine irritates the skin, eyes, and lungs. Breathe a little and you end up coughing or with a raw throat. Take too much, and your lungs might spasm or fill with fluid. Wipe it across your skin and you might spot blisters. If it gets in your eyes, there's a real risk of lasting damage. I’ve seen a coworker miss tiny droplets on his goggles and complain about burning for days. The smell alone gives you a heads-up to move away, but sometimes it lingers at the edge of your awareness, especially in a busy space.

This chemical catches fire and lights up violently. All it wants is an ignition source. Keep an open container near sparks, and you’re asking for a story that ends badly. It forms explosive mixtures with air at room temperature. Any buildup in a poorly ventilated area sets off alarms for good reason.

If you think you’re exposed, get away from that area. No heroics—just leave quick. For anyone breathing fumes, get them to fresh air. Take off any contaminated clothing right there. Don’t let panic cause mistakes; stripping off the affected gear limits how much skin gets hit. If they’re coughing or having trouble, call for medical help. Helping someone breathe easier gives the biggest boost. Cover them with a blanket if they seem shocked, but don’t crowd around.

Skin contact means a long rinse with plenty of water. Most guides mention at least 15 minutes, but honestly, I recommend rinsing until the burning stops, no matter how long. Remove rings, watches, or anything else that could trap chemical against the skin. Don’t bother with creams or ointments until a doctor says it’s safe. For eyes, get under running water and hold lids apart. Anyone who’s needed an eyewash station will tell you those first seconds matter. Don’t rub, just flush. Even if pain drops off quick, playing it safe with an eye specialist makes sense.

Ingestion is rare, since nobody willingly swallows a stinky chemical. If it happens, don’t reach for milk or anything like that—instead, focus on getting medical help. Never try to make the person vomit. Quick calls to poison control set you up to handle the crisis properly.

Protective gear cuts most of the risk, but no equipment is perfect, especially after a long shift or rushed cleanup. Training helps you spot leaks before anyone gets hurt. Good ventilation, working detectors, and simple routines like handwashing and sealing lids all build layers of safety. Shortcuts eventually catch up with you.

Companies can do more than drop a thick safety binder on a table. For me, practical rehearsals—actual spills, fake emergencies—teach faster than anything printed on paper. Pair that with honest reporting and a boss who listens, and you end up with fewer surprises. Dimethylamine’s no joke, but steady habits turn a tricky workplace into a safer one, job after job.

| Names | |

| Preferred IUPAC name | Methanamine |

| Other names |

DMA Dimethylazan Methanamine, N-methyl- N,N-Dimethylamine |

| Pronunciation | /daɪˌmiːθɪlˈæmiːn/ |

| Identifiers | |

| CAS Number | 124-40-3 |

| 3D model (JSmol) | `dimethylamine|CCN` |

| Beilstein Reference | 605353 |

| ChEBI | CHEBI:17713 |

| ChEMBL | CHEMBL1403 |

| ChemSpider | 5791 |

| DrugBank | DB03788 |

| ECHA InfoCard | ECHA InfoCard: 100.000.039 |

| EC Number | 204-697-4 |

| Gmelin Reference | 52738 |

| KEGG | C01441 |

| MeSH | D003981 |

| PubChem CID | 6113 |

| RTECS number | IQ0525000 |

| UNII | F528464EMS |

| UN number | UN1160 |

| CompTox Dashboard (EPA) | DTXSID202020 |

| Properties | |

| Chemical formula | C2H7N |

| Molar mass | 45.08 g/mol |

| Appearance | Colorless liquid with a fishy or ammonia-like odor |

| Odor | Ammonia-like |

| Density | 0.674 g/cm³ |

| Solubility in water | Miscible |

| log P | 0.09 |

| Vapor pressure | 1690 mmHg (at 20 °C) |

| Acidity (pKa) | 10.73 |

| Basicity (pKb) | 3.27 |

| Magnetic susceptibility (χ) | -13.2 × 10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.369 |

| Viscosity | 0.23 cP (at 25 °C) |

| Dipole moment | 1.62 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 81.3 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -59.7 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1926 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS06, GHS05 |

| Pictograms | GHS02,GHS06,GHS05 |

| Signal word | Danger |

| Hazard statements | H220, H311, H314, H331 |

| Precautionary statements | P210, P260, P261, P271, P280, P301+P312, P304+P340, P305+P351+P338, P311, P335+P334, P337+P313, P363, P370+P378, P403+P233, P405, P501 |

| NFPA 704 (fire diamond) | 2-4-2-Acide |

| Flash point | -6 °C |

| Autoignition temperature | 427 °C |

| Explosive limits | 2.8% - 14.5% |

| Lethal dose or concentration | LD50 oral rat 698 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat 698 mg/kg |

| NIOSH | NIOSH: JF7910000 |

| PEL (Permissible) | 10 ppm |

| REL (Recommended) | 5 ppm |

| IDLH (Immediate danger) | 100 ppm |

| Related compounds | |

| Related compounds |

Methylamine Trimethylamine Ethylamine Diethylamine |