Back in the early 19th century, chemistry students and tinkerers ran into all sorts of unknown liquids, sniffing around the edges of aliphatic amines long before much was written down. The bigger breakthroughs in organic synthesis brought dibutylamine into sharper focus—especially as petrochemicals and industrial solvents gained traction in the last century. Once the world needed better corrosion inhibitors and rubber chemicals, companies started cataloging dibutylamine, giving it a place in chemical directories instead of letting it fade behind its more famous cousin, triethylamine. Over time, labs created safer and more precise ways to prepare it, increasing purity and making it effective in more than just specialty processes.

Found in drums or bulk in a colorless liquid form, dibutylamine isn't flashy but has built a quiet reputation as a crucial intermediate. People who handle chemical syntheses recognize it by its mild, fish-like odor. Many industrial sites stock it for its role in manufacturing pharmaceuticals, pesticides, rubber accelerators, and corrosion inhibitors. Chemical suppliers list dibutylamine under CAS number 111-92-2, with the name itself standing for N-Butyl-1-butanamine. The product has a density around 0.77 g/cm³ and a boiling point that edges near 159°C. Whether in the fertilizer plant or the lab prepping surfactants, folks count on its reliability and consistent behavior when put to work.

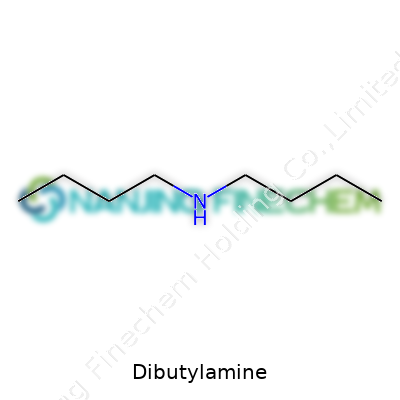

Dibutylamine exists as a clear, oily liquid. Its vapor pressure tends to be low, but not negligible, making ventilation a real concern in closed spaces. The amine group gives it basicity, so it catches on to acids quickly and creates salts without drama. Another quirk: upon storage, dibutylamine can absorb carbon dioxide from air, slowly forming carbamates, so keeping it sealed proves smarter than leaving it out. Its structure—two butyl groups attached to nitrogen—delivers a balance between oil-like solubility and enough volatility to be distilled if needed. In water, it's only slightly soluble, which influences how cleanups go after spills.

Manufacturers label standard product for over 99% purity, with the rest mostly water and low-level byproducts from its own production. Safety data sheets assign UN 2248, tying it to dangerous-goods transit rules, pushing handlers to use chemical-resistant gloves and facial protection. Bottles often carry pictograms for “harmful,” signaling possible irritation to skin and eyes, not to mention what happens if somebody breathes its vapor for too long. Nobody should eyeball the labels lightly; even the most experienced workers get a rush from a tiny whiff that says more about safety than about pleasant chemistry.

Turning butylamine and butyl alcohol into dibutylamine isn't magic but takes planning. Hydrogenation of butyronitrile gets the nod industrially because it makes the process scalable for big batches. Some chemists use reductive amination of aldehydes with ammonia, but that approach requires tight temperature and pressure control. Labs sometimes tinker with direct amination of 1-chlorobutane over catalysts, seeking better yields while cutting down on unwanted byproducts. Over time, companies have squeezed out more product for every barrel of input, raising yields and reliability without throwing a wrench in reactor safety.

With its two butyl chains dangling from a nitrogen atom, dibutylamine reacts easily with acid chlorides to form amides used in pharmaceuticals and plastics. Its lone pair of electrons makes it a base that soaks up protons and neutralizes strong acids in chemical spills or waste streams. Alkylation—adding more carbon chains—can nudge properties for specialty tasks. It forms stable salts with mineral acids, enabling easy isolation or transport in safer, less-volatile forms. In combination with formaldehyde, it helps generate Mannich bases, which end up in drugs and epoxy resin hardeners, showing chemistry’s knack for connecting the dots to far-off markets.

Dibutylamine goes by several handles: N-Butyl-1-butanamine, DBA, and Butylamine, N,N-dibutyl- fill out industry sheets and customs paperwork. In pharmaceuticals, trade names might crop up depending on country of use and application. There’s no room for confusion when hazard labels are involved, but paperwork often group dibutylamine under broader “amine intermediates” for simplicity. If shipping across borders, picking the right synonym keeps customs from holding up production lines or delaying urgent shipments.

No matter the lab or factory, teams lean on strict standards for handling dibutylamine. Contact with skin causes burns, especially after long exposure or when concentrations go unmonitored. Ventilation matters more than ever—fume hoods, extractor fans, and personal protective equipment work together to keep inhalation risks in check. Chemical-resistant gloves—nitrile over latex—block seepage, and splash goggles stop careless splatters from ruining eyesight. Facilities store dibutylamine in cool, dry places away from acids and oxidizers. Emergency protocols drill for spills, including using absorbent pads, sealing off drains, and cleaning up before the vapors drift across open workspaces.

Dibutylamine crisscrosses heavy industry and specialty manufacturing. Making rubber chemicals, especially vulcanization accelerants, puts it on the radar of tire and gasket factories. In corrosion inhibition, refineries and water treatment plants trickle it into pipelines and tanks, stretching out equipment lifespans and slashing repair bills. Pharmaceutical synthesis sees dibutylamine playing behind-the-scenes, building blocks for antihistamines and intermediates for certain heart medications. Agriculture taps into its chemistry for crop-protection agents. Despite the hazards, it underwrites industrial efficiency, often replacing heavier, dirtier amines for cleaner chemistry downstream.

Universities and industrial R&D push dibutylamine toward green chemistry. Newer catalysts cut energy use and wastes during production, aiming for smaller environmental footprints. Scientists test biodegradable derivatives, looking to meld performance with better end-of-life profiles. Analytical chemists refine methods to gauge trace impurities, since tiny bits can throw off reactions if left unchecked. Collaboration between university labs and chemical producers speeds up innovation, often leading to patents for safer, more efficient dibutylamine syntheses or new applications in materials science. Breakthroughs move from pilot plants to full-scale production, feeding new sectors hungry for amine intermediates.

Animal studies and worker surveys laid out risks linked to exposure: skin and eye burns, respiratory irritation, and at higher doses, nervous system effects. Chronic exposure stirs up longer-term questions about kidneys, with some rodent studies showing changes after repeated contact. Regulatory agencies assign occupational exposure limits, pushing companies to monitor air quality with sensors and badges for workers. Drinking-water contamination scares have forced tighter tracking from shipping ports to final use. Toxicity research plays catch-up with real-world incidents, as safety protocols update in response to what happens, not just what’s predicted in a textbook.

Environmental rules grow tighter each year, so manufacturers look for cleaner ways to produce, use, and dispose of dibutylamine. Research into closed-loop systems, where almost zero waste leaves the plant, has attracted investment. Companies test new byproducts for value in adjacent industries, shifting perceptions from hazardous waste to untapped resource. Green chemistry trends demand products that break down safely, pushing dibutylamine derivatives towards better environmental profiles. As supply chains stretch across continents, tracking and traceability systems could move into blockchain territory, ensuring safe handling every step from factory to end use. Efforts to replace hazardous solvents with safer amine analogs will shape the market. Even as automation slices labor risks, real improvement calls for better training, tougher air monitoring, and new kinds of protective gear, so tomorrow’s workers can handle dibutylamine and its cousins with fewer health risks than those who came before.

Dibutylamine doesn’t show up in household conversations, but you’d be surprised by the reach it has. If you work in agriculture, or know someone who does, chances are you’ve seen dibutylamine at work even if you didn’t realize it. This compound goes straight into the toolbox for making certain herbicides. It’s a stepping stone that helps companies build chemicals to keep weeds in check and crops productive.

All those hurdles farmers face with unwanted plants can eat up both time and money. Dabbling in farming as a kid, I saw how quickly dandelions or crabgrass could choke out a vegetable patch. It made me respect what goes into pest management on a larger scale, and how deeply these basic compounds matter.

Dibutylamine’s list of jobs doesn't stop at weed killers. Factories use it as a building block for other chemicals, especially those that need precise reactions. Think pharmaceuticals or rubber-making, where small shifts make a big difference in the final product.

If you hop into a car and hit the road, some of the parts that keep things running — gaskets or hoses, for example — benefit from chemical tweaks using dibutylamine. Rubber gets treated to stand up to heat, pressure, or age so those parts don’t break down too fast. I did a stint working for a tire manufacturer, watching techs mess with different formulas. This was a big eye-opener: small chemical tweaks can mean fewer breakdowns and safer travels.

Like a lot of base chemicals, dibutylamine comes with a need for respect. So many plants using it keep stocks locked down — you wouldn’t want it leaking out or mixing with the wrong things. Direct contact can cause skin or eye irritation, and breathing in its fumes pushes any worker to wear masks or work in well-ventilated spots. The times I’ve watched a chemical safety drill, the main point drilled into us was don’t slack off on your gear just because something looks clear or harmless.

On the environmental side, spills and leaks rarely get a second chance. Waterways and soil can suffer. That’s why more companies now lean on spill containment and better tracking systems. There’s been a steady push for stronger rules around storage and use, forced partly by past mistakes.

There’s no silver bullet, but some fixes look promising. The chemical sector can chase greener production. Some researchers push for alternative methods that give us the same effect with less impact during breakdown. It’s the kind of shift that usually takes time but pays off in the long run.

Training helps too. No shortcut beats people who know what they’re doing. Some companies update procedures every quarter, which helps everyone stay sharp. It may feel like extra paperwork, but it pays off with fewer accidents and safer handling.

In the end, dibutylamine underlines a bigger picture. Even basic compounds reach into everyday life, from food production to safer cars. With better awareness and smart choices, it’s possible to keep reaping the benefits while cutting down the risks.

Dibutylamine shows up in more places than people expect. Factories turn to it for rubber processing, pharmaceuticals, even some pesticides. It’s a colorless liquid with a strong, fishy odor and if you’ve ever stepped near a chemical plant, you might know that smell even if you can’t name it.

Getting this chemical on your skin or in your eyes burns and stings. It causes redness, swelling, and enough discomfort to make most folks never want to go near it again. I once helped move barrels in a warehouse where a drum leaked. Even with gloves and a face shield, I felt my skin tingle after a brief brush. Some co-workers spent the following day with itchy rashes. There wasn’t a day we weren’t told to wear gloves and goggles, but accidents still happened.

Inhaling vapors leads to coughing, chest tightness, sore throat, and headaches. Some heavy exposures irritate lungs so much that workers need medical attention. Even a quick whiff feels harsh, like breathing near bleach. Chronic exposure doesn’t just make you uncomfortable – it can cause lasting harm if ignored.

Swallowing dibutylamine isn’t just a bad idea, it’s dangerous. Animal studies show damage to internal organs when taken in high doses. It upsets the stomach, damages liver and kidneys, and, in some cases, might even mess with blood chemistry. There haven’t been enough studies on people, but reason tells us not to gamble with ingestion.

Anyone spending years handling dibutylamine could face bigger risks. Some European health panels flagged it as a concern for people with sensitive airways. The International Agency for Research on Cancer hasn’t found enough to call it a carcinogen, but anything that irritates the mucous membranes this much keeps folks wary. No hobbyist should keep this stuff around for DIY uses.

Plenty of manufacturers issue strict safety guidelines, and for good reason. Gloves, goggles, and sealed ventilation systems cut down on accidental burns or lung damage. A friend of mine who supervises a chemical plant sees all new staff get safety briefings about dibutylamine and similar substances; regular training stands as their most important shield. Yet mistakes keep happening, often because someone skips protective gear during “just a quick task.”

Stronger workplace rules do help, but they need constant reinforcement. Good practice means swapping out any worn gloves, keeping eyewash stations close by, and never assuming a fast job is risk-free. Employees should report every leak or spill, no matter how small. Companies that keep open records of these incidents end up with safer workplaces because people learn from others’ slip-ups.

Disposal deserves attention too. Dumping dibutylamine with regular trash or drains poses a threat. It seeps into soil and groundwater. Community hazardous waste collection programs help by handling chemicals the right way. Anyone who finds old containers tucked away in a shed should let local waste agencies deal with them—not bury them behind the house.

Dibutylamine won’t jump out and get you, but ignoring its risks creates big problems. Whether in a large factory or out in the community, treating it with respect protects workers, families, and the local water supply.

Dibutylamine stands out in the world of amines thanks to its unique molecular structure and industrial significance. Its chemical formula, C8H19N, may look like a jumble at first glance. For someone like me, not a chemist by trade, this formula boils down to eight carbon atoms, nineteen hydrogen atoms, and just one nitrogen atom, all linked together. Picture two butyl groups (basically long, snaking carbon-hydrogen chains) attached to a single nitrogen. This isn't the sort of chemical that sits on kitchen shelves, yet it quietly finds its way into many items around us.

Put simply, the makeup of Dibutylamine lets it act as a sort of building block for a string of different things. Its nitrogen atom opens doors to chemical reactions that pure hydrocarbons can’t tackle. That’s why companies look to C8H19N when time comes to make rubber accelerators, pesticides, medicines, and dyes. To be blunt, chemistry transforms dirt, oil, and even dangerous stuff into products we take for granted: from shoes to car tires, household detergents to colorants in your favorite jeans.

Before stepping into this world, it often struck me as odd that one tweak to a molecule changes everything. Swap a few atoms, and you’ve got an entirely new chemical, one that might treat headaches or help shape a phone casing. With Dibutylamine, this flexibility means factories keep churning out the materials that shape everyday life.

Not many people stumble across Dibutylamine outside of labs or factories. For those handling it, though, there’s risk. This stuff smells fishy—literally—and it’s no picnic if it splashes on your skin or releases vapors. Exposure can irritate the nose, throat, and lungs, much like what you’d feel when scraping burned toast, only worse. Getting chemicals like this under control isn’t just a matter of good sense; it’s a duty. Exhaust ventilation and gearing up with gloves and goggles make working conditions safer but not perfect.

In my days working alongside industrial maintenance teams, the message was always clear: never skimp on safety, even if deadlines scream your name. Problems erupt when shortcuts pile up—leaky drums, poor storage, or a missing respirator. Breaking this habit needs both personal commitment and clear workplace standards. Sometimes small companies shrug off bigger worries. That’s why local regulations and regular training matter.

For starters, the industry could step up transparency. I’ve seen too many product labels with codes instead of real information, and that leaves workers and consumers guessing. Clear info gives people a fighting chance to avoid nasty accidents or reactions. Training helps, but real progress grows out of a culture that takes safety as seriously as profit. Affordable monitoring equipment or simple leak detectors could tip the scales for small businesses.

Far beyond keeping pages of regulations, a real shift would mean making chemical handling second nature for everyone in the chain. Teaching not just the “how” but the “why” leads to a more responsible workforce. Step by step, that’s how you keep folks safe and keep molecules like C8H19N quietly doing their job—out of sight, but not out of mind.

Dibutylamine isn’t something most people toss in a shed and forget about. This chemical gives off strong fumes and catches fire much faster than you might expect. I’ve seen old warehouses with rusty drums sweating out a faint fishy smell—nobody wants that in their workspace or neighborhood. Just one careless move in storage could risk fires, leaks, or health issues.

Heat and sunlight don’t play well with dibutylamine. Leaving barrels in a spot where sun shines all afternoon leads to swelling, strong vapors, and a much greater risk of the stuff breaking down. I’ve worked in labs where we learned the tough way: a warm storage room costs you peace of mind, because that’s asking for pressure buildup or evaporating fumes.

A shady, dry, and well-ventilated room gives you the best option. I’ve seen folks try improvising storage in basements, but mold and dampness seep in fast down there—and dibutylamine reacts pretty badly if it finds water. Humidity rusts containers and that leads to leaks, which wrecks both the product and your storage area.

The biggest mistake? Leaving the chemical in a barely closed or unlabelled container. I’ve had to clean up the mess left behind by someone who “thought they’d come back in a minute.” Air sneaks in, the liquid evaporates, and before you know it, you’re guessing what’s in the drum by smell alone. Strong, airtight lids save more time and money than any lock.

Next, never keep dibutylamine close to acids or oxidizers. These chemicals love to pick fights, and it rarely ends well. That lesson hits especially hard after a fume hood fills with choking, soapy smoke. Good labeling and separation cut down on risk and help everyone sleep easier, knowing a clumsy hand won’t set off a reaction.

You can get away with the wrong container once or twice; pressboard always buckles and everyday plastics start softening and leaking way too soon. The right choice—sturdy steel drums with corrosion resistance—pays off with fewer spills and easier handling. Not every workplace splurges on the best barrels, but once a spill hits, nobody’s counting pennies anymore.

A lot of sites keep a spill kit handy, and that shows a real understanding of what can go wrong. I always check for these on my first walk through any workshop dealing with hazardous stuff. Absorbent pads, basic breathing masks, and heavy-duty gloves can stop a small mistake from turning into an all-day crisis.

Storage doesn’t mean much if folks cut corners with safety. The best set-up in the world fails if employees rush, skip checks, or ignore warning signs. I’ve watched teams gather for short talks about chemicals before each shift, and the places where daily practice matched the plan always fared better. Training sticks with you, especially after seeing what a minor leak can do.

Regulations exist for a reason, but everyday routine keeps things working. Double-checking labels, keeping inventory tight, and inspecting seals stop trouble before it starts. If you’ve never dealt with a chemical leak, believe me: prevention really means everything.

Dibutylamine usually lives stashed on an industrial shelf, mostly unknown to folks outside certain labs or factories. It’s tricky stuff — colorless, with a strong odor, so you might notice it even before you read the label. Many chemicals, even familiar household ones, can cause trouble if handled the wrong way. Dibutylamine ramps it up another notch, since it packs some real risks: skin burns, breathing problems, headaches, and even nastier effects if someone is unlucky.

Experience teaches that trouble with chemicals often comes from people just underestimating how exposure happens. Just opening a bottle or pouring a bit can be enough, because dibutylamine gives off vapors easily. Gloves and goggles aren’t there for show; they keep this liquid out of your blood and away from your eyes. Folks who’ve seen chemical splashes land someone in urgent care don’t take shortcuts. A cotton T-shirt or cheap gloves don’t cut it – someone needs the real gear: nitrile gloves, a snug pair of goggles, and a trusty lab coat. The smell alone signals it’s time to ramp up protection, not power through.

Hanging a “well-ventilated area” sign isn’t just compliance. Good air flow saves people, not paperwork. Fume hoods should already be humming before cracking the seal on a bottle. At home, I’ve seen DIYers open paint thinners in a closed garage and nearly pass out. Dibutylamine can do much more harm, so decent fans and fume extraction aren’t extras – they’re basics. If breathing starts to feel weird or eyes burn, it’s time to hit fresh air and see a supervisor, not tough it out.

I’ve seen containers left out “for a minute” turning into overnight accidents. Dibutylamine wants a cool, dry spot, sealed tight and well labeled. Away from acids, too, since mixing these two by accident kicks up toxic fumes that can clear a whole building. Forget about using a broken, beat-up container. Secure lids and those chemical-resistant labels sure beat confusion or a dangerous mistake. Think of storage as part of the job – not something to rush through on the way to lunch.

Spills happen—sometimes from a bump, sometimes from a tired hand. The usual mop and bucket routine won’t cut it. Instead, there’s an order: block off the area, gear up, soak up liquid with absorbent materials, and bag everything right. Water just spreads dibutylamine, so no old habits with the mop. In some shops, people rehearse spill drills so nobody fumbles on the real day. That kind of practice shaves precious seconds and keeps injuries down.

Safe handling isn’t about fear; it’s about respect. Dibutylamine’s hazards stand out, but so do the lessons. Ask the team that’s been there – veterans often share stories new folks never forget. Face shields, gloves, clean workspace, and good habits might look annoying compared to shortcuts, but they keep people going home unharmed. Safety data sheets (SDS) gather dust someplace, but the smart operators keep them close, not just for inspectors but for daily questions. Read them. Reference them. That approach kept my old mentor’s team out of trouble for decades, and it still works today.

| Names | |

| Preferred IUPAC name | N-butylbutan-1-amine |

| Other names |

Dibutylamine N-Butyl-1-butanamine N-Butylbutan-1-amine Di-n-butylamine |

| Pronunciation | /daɪˈbjuːtɪl.əˌmiːn/ |

| Identifiers | |

| CAS Number | 111-92-2 |

| Beilstein Reference | 635873 |

| ChEBI | CHEBI:38894 |

| ChEMBL | CHEMBL14008 |

| ChemSpider | 5267 |

| DrugBank | DB01957 |

| ECHA InfoCard | 100.060.361 |

| EC Number | 204-680-3 |

| Gmelin Reference | 8417 |

| KEGG | C01741 |

| MeSH | Dibutylamines |

| PubChem CID | 8183 |

| RTECS number | KH8575000 |

| UNII | HD6U63001A |

| UN number | UN2244 |

| CompTox Dashboard (EPA) | DTXSID2022886 |

| Properties | |

| Chemical formula | C8H19N |

| Molar mass | 129.24 g/mol |

| Appearance | Colorless to yellow liquid with an ammonia-like odor |

| Odor | Ammonia-like |

| Density | 0.728 g/mL at 25 °C (lit.) |

| Solubility in water | Miscible |

| log P | 1.68 |

| Vapor pressure | 0.69 kPa (at 20 °C) |

| Acidity (pKa) | 10.98 |

| Basicity (pKb) | 3.35 |

| Magnetic susceptibility (χ) | -6.18×10⁻⁶ |

| Refractive index (nD) | 1.426 |

| Viscosity | 0.92 mPa·s (20 °C) |

| Dipole moment | 2.75 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 229.6 J⋅mol⁻¹⋅K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -19.7 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3890.7 kJ/mol |

| Pharmacology | |

| ATC code | D11AX15 |

| Hazards | |

| Pictograms | GHS02,GHS05,GHS06 |

| Signal word | Danger |

| Hazard statements | H302, H312, H314, H332 |

| Precautionary statements | P210, P261, P264, P271, P280, P301+P312, P303+P361+P353, P304+P340, P305+P351+P338, P311, P312, P330, P337+P313, P362+P364, P370+P378, P403+P233, P405, P501 |

| NFPA 704 (fire diamond) | 1-3-0-A |

| Flash point | 61°C |

| Autoignition temperature | 287 °C |

| Explosive limits | 1.1% - 10.6% |

| Lethal dose or concentration | LD50 oral rat 600 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral, rat: 406 mg/kg |

| NIOSH | NIOSH: IM4025000 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) of Dibutylamine: "5 ppm (15 mg/m³) as an 8-hour TWA (OSHA) |

| REL (Recommended) | 10 ppm |

| IDLH (Immediate danger) | 100 ppm |

| Related compounds | |

| Related compounds |

n-Butylamine Diethylamine Dipropylamine Triethylamine Tributylamine Monobutylamine Isobutylamine |