Digging into the story behind 3-Hydroxy-5-Methylbenzonitrile opens a window to the steady progress of organic chemistry over the last century. Chemists have always looked for ways to add new tools to their synthetic toolbox, and this compound, also known as m-Cresolcarbonitrile, cropped up as folks got a firmer grip on reactions involving aromatic rings and functional groups. Early chemists leaned on coal tar derivatives for molecules like this one. Later on, access improved thanks to more direct routes, with improvements in precision and industrial scalability. Today’s methods avoid the waste and inefficiencies of the past, but the first curiosity about benzonitrile derivatives dates back to a time before widespread use in pharmaceuticals and materials science, when researchers just wanted to see how far ring substitution could go.

Commercially available 3-Hydroxy-5-Methylbenzonitrile comes as a crystalline solid or powder. Suppliers package it for stability and ease of handling, often in sealed bottles or drums. Today’s demand focuses on use as an intermediate in pharmaceuticals, fine chemicals, and specialty materials, which means buyers want both purity and traceability. One doesn’t see it sitting on retail chemical shelves, but rather in research labs and production facilities focused on advanced synthesis. Given its functional groups, it serves a niche but growing need in structural modification, particularly where precision is essential.

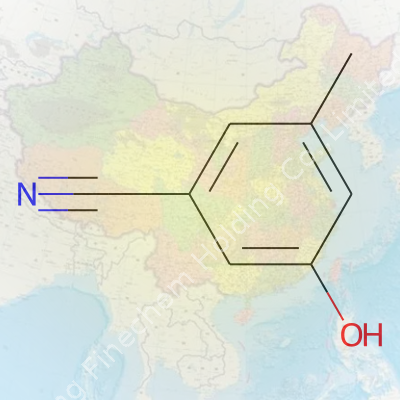

3-Hydroxy-5-Methylbenzonitrile carries the molecular formula C8H7NO. It usually appears as an off-white to beige solid, with a melting point reported between 113-117°C. Its molecular weight hovers around 133.15 g/mol. The nitrile group brings strong polarity, yet the presence of both methyl and hydroxy groups on a benzene ring affects solubility and reactivity. It dissolves moderately in polar organic solvents, such as ethanol and acetone, but resists solubility in water, reminding one of the challenges faced in aqueous-phase synthesis. The phenol group, positioned opposite the methyl substituent, imparts reactivity for further functionalization, while the methyl group tweaks the ring’s electron distribution. These small changes in structure can drive major differences in downstream chemical behavior.

Quality control for 3-Hydroxy-5-Methylbenzonitrile encompasses appearance, purity, and residual solvents. Most suppliers demand a minimum purity of 98%, supported by GC or HPLC analysis. Labels provide CAS number (2499-39-4), batch number, net weight, and hazard pictograms in compliance with GHS regulations. Documentation traces each lot’s synthesis and analytical results, sometimes including IR and NMR spectra on demand. Transport labeling highlights flammability and toxicity concerns, prompting the need for secure storage away from open flames and oxidizing agents. For those used to dealing with standards, it’s familiar territory: careful tracking and secure, coded packaging.

Lab-scale and industrial producers often rely on a modified Sandmeyer reaction or oxidative routes starting from 3-amino-5-methylphenol or the parent methylhydroxybenzene. Nitrilation using copper(I) salts and sodium nitrite delivers the nitrile function, often under basic conditions to avoid unwanted side products. This method takes patience, as reaction temperatures and pH require close watch. Purification may involve recrystallization from ethanol or ether, balancing yield and purity in every batch. For those in process chemistry, minimizing byproducts and maximizing atom economy keeps the accountants happy and the regulators at bay.

The beauty of 3-Hydroxy-5-Methylbenzonitrile in synthetic chemistry comes from its reactive spots: that phenolic hydroxy handles alkylation and acylation, while the nitrile group undergoes transformations to carboxamides, acids, or amines via catalytic or chemical reduction. Electrophilic substitutions, like bromination or sulfonation, still work, depending on the solvent and conditions. Some folks leverage the methyl group for chain extensions, though most see it as a way to fine-tune electron density. Each modification opens a door to new scaffolds in medicinal chemistry, such as bioactive heterocycles and agrochemicals.

This compound pops up under a few names across databases and supplier catalogs: m-Cresolcarbonitrile and 5-Methyl-3-hydroxybenzonitrile stand as the most common synonyms. European suppliers might label it as 3-Hydroxy-5-methylbenzenecarbonitrile. Some specialty catalogs refer to it with internal alphanumeric codes, but the CAS number (2499-39-4) remains the surest way to avoid confusion when ordering samples across borders or speaking with custom synthesis companies.

Working with 3-Hydroxy-5-Methylbenzonitrile calls for standard chemical safety routines. Users don gloves, goggles, and lab coats. The dust, if inhaled, can cause irritation, so fume hoods come into play for weighing and transfer. Emergency documentation details routes of exposure, which primarily involve irritation to eyes, skin, and the respiratory tract. Chemical storage practices require a cool, dry area, sealed from moisture and incompatible reagents. Waste disposal falls under organic hazardous, so professionals rely on certified disposal companies. Training for emergency spills ensures that nobody learns the dangers the hard way. Personally, there’s a calm confidence that comes from knowing the routine and understanding the hazards, rather than hoping instructions alone will keep everyone safe.

The main pull for 3-Hydroxy-5-Methylbenzonitrile comes from researchers and industrial chemists tackling pharmaceuticals, agrochemicals, and material science. Medicinal chemists reach for it to build precursors for drugs where the benzonitrile scaffold brings metabolic stability or target affinity. Agrochemical companies exploit its structural motif in herbicides and fungicides, counting on its chemical backbone to stand up to environmental factors. Polymer and dye industries keep an eye on its aromatic system, tweaking side groups as needed for performance. Demand rises and falls as new patents get filed and old ones expire, with innovation driving the next spike.

Academic labs and R&D units in major corporations keep testing the limits of 3-Hydroxy-5-Methylbenzonitrile. Methods for greener and safer synthesis get published each year, addressing cost, byproducts, and energy use. Automated platforms and flow chemistry setups enter the scene, making small- to mid-scale experiments easier to reproduce and scale. In medicinal chemistry, SAR (structure–activity relationship) studies use the compound as a jumping-off point to produce variations that might deliver a better therapeutic profile or reduce toxicity. Chemoinformatics plays its part as well, with digital models screening derivatives before anyone commits to wet-bench work.

Published data suggests moderate acute toxicity by ingestion or inhalation. Studies point out irritant properties but not strong mutagenicity or carcinogenicity based on initial screens. Animal trials remain limited, but existing data pushes most users to err on the side of caution. Long-term effects on humans stay underexplored, so firms carrying out large-scale work conduct in-house tests or contract GLP-compliant toxicology labs before moving toward production quantities. Environmental fate draws attention, too—nitrile compounds sometimes break down into potentially harmful metabolites, and so effluent controls get dialed in tightly. Conversations with regulatory agencies in both Europe and the US stress the need for ongoing research, since gaps in knowledge could block approvals for any end-use products.

Looking ahead, 3-Hydroxy-5-Methylbenzonitrile stands at the crossroads of chemical innovation and regulatory scrutiny. Interest rises as industries hunt novel, cost-effective synthetic intermediates that align with sustainability goals. Green chemistry continues to inform its production, with new catalysts and solvents aiming to cut waste. Bio-based routes may open possibilities for renewable feedstocks, responding to both market pressure and policy mandates. As medicinal and agricultural needs evolve, especially in the quest to beat resistance and improve selectivity, this molecule has a chance to anchor the next series of discoveries—assuming scientists can keep safety and environmental impact in check as demand grows.

Chemistry students and researchers like to ask about molecules that don’t regularly pop up in household products. 3-Hydroxy-5-Methylbenzonitrile is one of those compounds that hides in plain sight on chemical supply catalogs. The formula reads C8H7NO. That tells a story: eight carbons, seven hydrogens, one nitrogen, a single oxygen, all arranged in a very specific pattern on a benzene ring. The molecular weight checks out at 133.15 g/mol.

So, what difference does one hydroxy group make? The presence of hydroxy at the third position cranks up the reactivity compared to plain benzonitrile, giving chemists options for follow-up reactions. The methyl group at the fifth position helps tweak electronic properties, which can alter how this molecule interacts with other chemicals, whether that’s in a flask or eventually in a high-performance polymer or specialist dye.

I’ve seen labs where swapping out a methyl for some other small group turned a non-performing drug candidate into something a client seriously considered. The tiniest changes on a benzene ring can unlock a big box of possibilities for new molecules.

A molecular weight of 133.15 makes this compound attractive when planning reactions that require quick diffusion through solutions. Lower molecular weight keeps things moving in solvents. In my own work, setting up chromatography columns, compounds in this range usually elute in the sweet spot—not stuck to the resin, not off the column before you can blink.

Ask any grad student in synthesis about yield headaches, and you’ll often hear about the messiness from heavier, stickier molecules. Working with something perched around 133 g/mol brings a bit more predictability.

Everyone’s had a class where formulas feel abstract, but those chemical numbers drive powerful decisions. Planning an industrial route to a material? Too much nitrogen and oxygen, and safety protocols change. Make a small error with a molecular weight, and the final yield projections crumble. People who don’t check these details early wind up with wasted reagents and, worse, lost time.

This compound’s formula isn’t just trivia. Many pharmaceutical and agrochemical intermediates start as benzonitrile derivatives. Labs are always hunting for clever tweaks: a methyl here, a hydroxy there, hoping the right placement enhances bioavailability or branches into a new pesticide. In my own reading of patent databases, a surprising number of protected solid-state materials rely on small, seemingly insignificant derivatives like this one.

Supply chains now adapt to custom molecules for more flexible production. Sources providing pure 3-Hydroxy-5-Methylbenzonitrile need to verify that formula, that molecular weight, and the isomer placement. Otherwise, you’re not just risking an off-target reaction—you could set back a program by months.

It’s not about vanity or chemical trivia. Precision with formulas cuts through confusion, lets teams collaborate, and gives risk-averse managers some peace of mind. The right details up front save everyone on the backend, whether you’re tinkering with dyes in a research lab or scaling up for new polymers.

Manufacturers and academic chemists could do more to share verified analytical data for each variant. It’s a fair ask: specs for 3-Hydroxy-5-Methylbenzonitrile are not hard to double-check and share online. If more suppliers contributed verified spectral data or open-access melting points for these smaller molecules, downstream users could work with better confidence. Nobody wants to repeat a synthesis only to discover a substituent in the wrong spot thanks to an ambiguous supplier label.

You don’t hear much about 3-Hydroxy-5-Methylbenzonitrile around dinner tables, but this mouthful of a compound helps keep labs and industries running. I came across its name years ago while reviewing some pharmaceutical chemical charts for a story, thinking it would be a short entry best skipped. That notion changed once I started digging past the surface. There’s a particular kind of buzz in the specialty chemicals world for small aromatic molecules like this, and curious minds soon find a web of links between them and real, everyday products.

Drug development lives and breathes by having access to a wide variety of reliable building blocks. 3-Hydroxy-5-Methylbenzonitrile, with its distinct nitrile group and convenient methyl at just the right position, fits this need for medicinal chemists. Folks in the labs turn to this compound as a starting point for making all sorts of experimental molecules, often aiming for new drugs. In fact, chemists use it to build up benzamide derivatives and pyridine-like structures, which show up often in antifungals, antivirals, and anti-inflammatory agents. Clinical trials usually fail more often than they succeed, but having flexible starting points like this one makes exploration faster and a bit less expensive.

I met an analytical chemist in a textile plant years ago, and our lunch break became a lesson in just how involved a life these chemicals live. She explained how 3-Hydroxy-5-Methylbenzonitrile lands in dye labs, giving color scientists the skeleton for custom colors. Its reactivity means pigment makers can tag on groups that shift the wavelength of light absorbed, adjusting color and brightness. This process keeps everything from sports jerseys to high-end silk scarves looking sharp. Beyond just color, these changes affect things like stability in sunlight and wash cycles, shaping the way the material feels and lasts in the real world.

Talk to anyone who’s worked in agricultural chemical research, and you’ll hear just how picky companies are about their intermediates. This compound gets used as a middle step in making sulfonylureas, which turn up in herbicides. The structure allows scientists to attach different groups for selective weed targeting. I interviewed a crop scientist who pointed out that developing new herbicides often rides on finding intermediates that let them dial in selectivity and breakdown rates, so both effectiveness and lower environmental impact see improvements.

Many people look at long lists of chemical names and block them out, but each entry contributes something unique. Access to reliable and pure 3-Hydroxy-5-Methylbenzonitrile boosts the pace of designing better medicines and sustainable crop treatments, and it even sneaks into the production of new light-absorbing polymers and resins. Every time someone figures out a slightly improved synthesis—maybe a cheaper solvent or a lower temperature step—it means lower costs for the next innovation built on this backbone.

The demand for specialty chemicals keeps climbing as researchers chase cures for illnesses or greener pest controls. Each jump in production brings its own risks: contamination, overuse, and logistical headaches. Good stewardship—screening byproducts, tighter waste controls, transparent supply chains—makes all the difference. The community of chemists, regulatory workers, and workers in manufacturing keep an eye not just on creative breakthroughs, but also the side effects that risk moving too fast. In the end, chemicals like 3-Hydroxy-5-Methylbenzonitrile serve as a reminder that progress often depends on invisible links, built from hard work and careful attention.

There’s a lot more to the story than just a chemical’s name or the label on its bottle. 3-Hydroxy-5-Methylbenzonitrile—a name that sounds like it’s straight out of a lab manual—has a few quirks when it comes to where it stays and how it likes to be treated. Before you stash it on a shelf, you have to look twice at storage conditions. Moisture and air love to mess with chemicals like this. So, a sealed container, preferably glass or high-grade plastic, keeps this compound happy. If you’ve ever had sugar clump up in a humid kitchen, you already know that air and moisture make small problems big.

In my own experience, storing similar benzonitriles taught me that room temperature keeps things calm, but only if “room” really means cool and out of direct sunlight. Heat is usually nobody’s friend in the lab. Leaving bottles on sunny windowsills is asking for trouble. Think of medicine at home—constant temperature in a medicine cabinet works better than anywhere near the stove. That translates just as well here.

Placing 3-Hydroxy-5-Methylbenzonitrile next to oxidizers or strong acids makes chemists lose sleep. It’s a bit like not keeping matches right next to lighter fluid. If you throw incompatible chemicals together, the results can go south fast—unexpected fumes, weird reactions, and cleanups you’ll regret. I learned early on to keep shelves labeled, not just for the neat look, but to save time and avoid any chemical comedy. Store this compound away from anything that could trigger a reaction, sticking to solvents or materials it likes.

You can tell who respects the chemicals because they never stop wearing their gloves and goggles, even if the stuff seems “mild.” Inhalation and skin contact aren’t on anyone’s to-do list. I remember a friend’s rash after one splash of an aromatic compound—not this one, but close enough that I learned fast. Keep things tidy. If something spills, clean it up right away—no waiting.

Saving the planet isn’t just talk in the lab. Tossing unused chemical down the drain is a shortcut nobody wants to admit to, but it causes more long-term headaches for everyone. Most labs have a chemical waste plan written out. At home, I once kept old paint thinner around for too long and regretted it—fortunately, I found a hazardous waste collection before it caused real harm. It’s the same deal with more stubborn lab chemicals: stick to the waste guidelines, hand them over to professionals, and don’t try clever shortcuts.

If you’re ever in a room with too many open chemicals, you notice pretty fast that some compounds stink. Benzonitriles sometimes smell sharp, not something you want lingering. On top of that, low flash points or unexpected flammability can turn a simple mistake into a blaze. Fire extinguishers nearby save lives. I never felt silly reviewing where the exits are, or running emergency drills—boring in the moment, a relief if something ever goes wrong.

At the end of the day, safe storage and good handling habits protect more than experiments—they keep colleagues out of harm’s way. From labeling to ventilated spaces, small steps build up over time. In any lab, trust builds through experience, good communication, and a shared agreement not to cut corners, no matter how much you’re under pressure.

This chemical sounds like something from a high school chemistry final, but it has its place in science and industry. It's used mainly as a building block for other chemicals, especially in research labs. The name comes from the structure on the benzene ring—basically, it's tweaked so folks can create new compounds more efficiently.

Pulling the safety data sheet (SDS) for this chemical, you see warnings about eye and skin irritation. This isn’t something to take lightly. A small splash can cause redness and discomfort. Breathing in the dust might bother your lungs. Some chemicals only mess with your health after years of handling; others hit harder right away. This one leans toward the second group—it might not have the long-term dangers we worry about with carcinogens, but it will let you know if you’ve touched or inhaled it.

If you’ve ever worked in a lab or factory, you know the basics: gloves, goggles, maybe a face mask. People sometimes downplay personal protective equipment (PPE) because gloves feel uncomfortable or goggles fog up. Judging by the way 3-Hydroxy-5-Methylbenzonitrile is listed, skipping PPE isn’t smart. Even a small splash or dust cloud can cause problems. And if you spill it, the clean-up process involves more than a paper towel; you need absorbent material, good ventilation, and sometimes a fume hood.

Another part that often gets ignored: storage. Leaving it out on a bench or shelf increases the odds of an accident. Tight, clearly labeled bottles—kept out of reach of anyone not trained—make a difference. I remember one hectic afternoon in a college lab, when a careless moment left me with a mild chemical burn from something less reactive than this. Since then, I double-check every bottle and never pass up on safety gear.

OSHA and similar organizations set the ground rules for handling chemicals, but reading a checklist isn't the same as caring about your own safety and the safety of coworkers. 3-Hydroxy-5-Methylbenzonitrile proves that even compounds used mainly behind lab doors matter outside that world—spills and exposure don’t respect job titles or experience levels.

Training sessions and posted protocols make sense, but they only work if people stick to them. One solution is training that isn’t a two-minute video nobody pays attention to. Hands-on demos, regular refreshers, and an open-door policy for reporting spills or near-misses build the kind of workplace where safety catches on. I’ve seen labs where folks go out of their way to check in with new team members during risky tasks. That tone, set from leadership down the line, makes more of a difference than a binder of protocols gathering dust.

Accidents still happen, even to seasoned lab workers. Emergency eyewash stations and showers help, but only if they’re easy to find and not blocked by a pile of boxes. It pays to practice the emergency drill once in a while, even if it feels silly. Quick thinking usually follows regular practice, not just luck.

Some suggest switching to less hazardous chemicals if possible, but research rarely offers luxury swaps. If you deal with 3-Hydroxy-5-Methylbenzonitrile at work or school, strict storage, full PPE, real training, and regular drills can take this scary-sounding chemical and make it manageable. Risks don’t vanish, but you can shrink them well below panic mode.

In a world filled with specialty chemicals, folks often overlook the straightforward questions—like how pure something is, or what size bottle it shows up in. Talking about 3-Hydroxy-5-Methylbenzonitrile, the level of purity isn’t just some background detail. This compound usually comes in purities upwards of 98%, sometimes touching 99% when made for pharmaceutical uses or dedicated research. And it’s not about chasing some obsessive ideal—life in a lab gets a lot easier when you can trust what’s on the label. Years ago, I worked with a supplier who sent over a batch one tick less pure than advertised. You run a test, spot a mystery peak on your readout, and suddenly you’re wasting a week tracking down what should have been a simple reaction. A little extra on the purity front saves real time and real money.

Check the certificate of analysis that comes along with the chemical. It usually details not just the specified purity—let's say, 98% or above—but also mentions trace residual solvents or water. The less you see on that list, the less dancing around impurities you’ll be doing. If you’re making final products for humans or fine-tuning a catalyst system, you can’t afford hitchhikers in your feedstock. Any deviations might mean more headaches down the road, or worse, failed experiments.

Packaging for chemicals like 3-Hydroxy-5-Methylbenzonitrile often follows a pattern, simple enough that most folks don’t give it a second thought. Standard lab packs? You’ll find 1-gram, 5-gram, and 25-gram bottles across supplier catalogs. These work out for most high-value applications in research settings, where a dash here and a dash there keeps the work moving. In bigger operations—think pilot plants or scaled-up syntheses—I’ve seen up to 100 grams or sometimes even 250 grams, shipped carefully in sealed amber bottles for stability. Larger packaging becomes rare; the demand simply doesn’t call for barrels or drums unless some industrial niche wakes up needing it.

Ordering smaller vials might seem unnecessary if cash is tight, but chemicals like this can degrade or absorb moisture from the air every time the cap comes off. No one wants to see their expensive starting material clumped up or turning color after a few weeks. Suppliers aim to match demand, not just warehouse space. I’ve found most labs prefer several small bottles so stuff stays fresh, rather than cracking open one giant jar every time. It cuts waste and the risk of cross-contamination, especially in spaces where more than one researcher uses the same shared chemicals.

I remember learning the hard way about packaging mismatches. Once, we tried to save a little by buying a big container. In theory, everyone was fine with it. In practice, we lost more to spoilage and spills than we would have with ten small ones. The chemical’s shelf life dropped, and work ground to a halt while we waited for a fresh shipment.

So, whether you’re in pharmaceuticals, academia, or trying out a new synthesis route, check the purity and pick your packaging size with care. Demand more from your supplier if their standard sizes won’t cut it. Getting the right material, at the right purity and in the most sensible bottle, isn’t just a detail—it’s the backbone of reliable work in the lab.

| Names | |

| Preferred IUPAC name | 3-hydroxy-5-methylbenzenecarbonitrile |

| Other names |

3-Cyano-5-methylphenol 5-Methyl-3-hydroxybenzonitrile |

| Pronunciation | /ˈθriː-haɪˈdrɒksi-faɪv-ˈmɛθɪl-bɛnˈzoʊ.nɪˌtraɪl/ |

| Identifiers | |

| CAS Number | 87132-74-7 |

| 3D model (JSmol) | ``` 3d:JSmol?model=17 ``` |

| Beilstein Reference | 1097336 |

| ChEBI | CHEBI:28740 |

| ChEMBL | CHEMBL520998 |

| ChemSpider | 69117 |

| DrugBank | DB08332 |

| ECHA InfoCard | 03e21a82-1fad-490b-bad7-ca470bdbb626 |

| EC Number | 6368-52-1 |

| Gmelin Reference | 145559 |

| KEGG | C14468 |

| MeSH | D017962 |

| PubChem CID | 137032 |

| RTECS number | BY9400000 |

| UNII | 0ZK08IKR0K |

| UN number | Not assigned |

| Properties | |

| Chemical formula | C8H7NO |

| Molar mass | 133.15 g/mol |

| Appearance | White to off-white solid |

| Odor | Odorless |

| Density | 1.18 g/cm³ |

| Solubility in water | Slightly soluble |

| log P | 1.8 |

| Vapor pressure | 1.32E-3 mmHg at 25°C |

| Acidity (pKa) | 9.22 |

| Basicity (pKb) | 9.10 |

| Magnetic susceptibility (χ) | -60.2·10^-6 cm^3/mol |

| Refractive index (nD) | 1.5630 |

| Dipole moment | 2.67 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 260.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | –44.0 kJ·mol⁻¹ |

| Std enthalpy of combustion (ΔcH⦵298) | -4072 kJ/mol |

| Hazards | |

| Main hazards | H315, H319, H335 |

| GHS labelling | GHS07,Warning,H315,H319,H335 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H302 + H312 + H332: Harmful if swallowed, in contact with skin or if inhaled. |

| Precautionary statements | P261, P264, P271, P272, P280, P302+P352, P321, P363, P333+P313, P362+P364, P501 |

| Flash point | Flash point: "168.3 °C |

| LD50 (median dose) | LD50 (median dose) of 3-Hydroxy-5-Methylbenzonitrile: "Acute oral LD50 in rats is >2000 mg/kg |

| NIOSH | NA1221000 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for 3-Hydroxy-5-Methylbenzonitrile is not specifically established by OSHA. |

| REL (Recommended) | 10 mg/m³ |

| Related compounds | |

| Related compounds |

3-Hydroxybenzonitrile 5-Methylbenzonitrile 3-Methylbenzonitrile 4-Hydroxy-3-methylbenzonitrile 2-Hydroxy-5-methylbenzonitrile |