Organic amines saw their first glimpses in labs as researchers like Hofmann and Wurtz worked through the bewildering complexity of carbon-nitrogen bonding. The discovery of 2-Propylamine, also called isopropylamine, belongs to a lineage of amines whose properties, back in the late nineteenth and early twentieth centuries, felt both exciting and a little unpredictable. Scientists in those days didn’t always have the fancy instruments we use now, so identifying a clear formula—a simple C3H9N—became a bit of a milestone. Since then, this little amine popped up in more than a handful of stories about pesticides, medicine, and even the basic study of how alkylamines play with other chemicals. The story of 2-Propylamine reminds us that chemistry’s building blocks, no matter how humble, often link decades of curiosity and incremental understanding.

2-Propylamine, with its sharp, fishy odor, doesn’t win popularity contests in the warehouse. Its small molecular frame, sitting just a step above methyl and ethyl cousins, brings a lively chemical spirit to the table. In practice, people find it in clear liquids bottled tightly to keep the vapors at bay. Even one whiff in a poorly ventilated storeroom sticks in memory. Labs and factories don’t chase after it for its looks or smell, but for how smoothly it gets work done in synthesis, solvents, and building blocks.

Straight to the facts, this is a colorless liquid at room temperature with a boiling point of 32–34°C, which makes it easy to lose to the air if care slips. Water mixes with it surprisingly well, breaking a common rule for many small organic molecules. Maybe more important: it burns easily and its vapors cling in low places. The nitrogen lone pair sets up a basic tone—strong enough to pull protons in acid-base reactions and friendly enough to dissolve in organic solvents. Once, in a lab accident, a colleague dropped a bottle on the bench, and the room filled quickly with a biting scent that cleared out everyone until the air system caught up.

Suppliers often ship it at purities above 98%. Labels mark it with UN2733, and it will always show hazard pictograms for flammability and harmful effects. Documentation strictly details storage in cool, dry spaces away from heat or open flames. Documentation on the datasheets also spells out its molecular mass at 59.11 g/mol, density hovering close to 0.693 g/cm3 at 20°C, and flash points near -18°C. Containers need vapor-tight seals—leaks mean trouble, both for safety and for keeping your supply from drifting off into the ceiling vents.

The classic road starts with the alkylation of ammonia with propanol or propene, using catalysts and careful attention to pressure. Chemists use batch or continuous reactors, and waste needs careful handling due to the ease with which amines escape. A few students I coached tried a reductive amination route for practice: start with acetone and reduce it in the presence of ammonia and hydrogen—a clever shortcut if you have the right setup. The big players make use of propene reacting with ammonia over solid catalysts, a route that keeps efficiency up and costs down. Even in a small lab, making a few hundred grams isn't too complex if safety gets a front-row seat.

2-Propylamine responds quickly to acids, turning into salts that dissolve in water, which comes in handy for isolating or purifying the compound. It catches up fast with alkyl halides to build larger amine structures, a step often needed in pharmaceutical syntheses. With its basicity, it picks up protons and can be used to neutralize acids. Peroxide or oxidizing agents quickly break it down, so mixing should never happen in careless hands. Sometimes, I’ve seen over-enthusiastic undergrads try to dry it over sodium—watching that exothermic sizzle turn to panic speaks to just how lively this amine can get with reactive metals.

People call it by several names. The IUPAC name 2-propanamine shows up in academic settings. Catalogs often list it as isopropylamine, propan-2-amine, or IPA, though in the solvent world, IPA usually means isopropanol. Trade names rarely catch on with such a simple molecule, but international logistics registers never miss listing each synonym for clarity in shipment and compliant handling.

This amine calls for personal protective equipment. Splash-resistant goggles, gloves made from nitrile or neoprene, and lab coats serve as minimums. Eye and skin contact bring on rapid irritation, and inhaling the vapors digs at membranes fast enough to ruin an afternoon or worse. In one mishandled scenario during my early days in chemical engineering, a half-tight cap led to widespread nausea. Storage follows rules—well-ventilated areas away from acids, oxidizers, flames, or other ignition sources. Emergency showers and eyewash stations stay close by anywhere 2-Propylamine goes, and safety data sheets demand no less.

Factories use 2-Propylamine in herbicides (atrazine crops up often in the references), pharmaceuticals, and the processing of rubber. Its ability to shape into intermediates means agrochemical companies lean on it heavily for bulk syntheses. Some corrosion inhibitors start with it as a basic building block. Paints and coatings sometimes take up modified forms for crosslinking agents or to change surface interaction. In small lab scales, it can serve as a teaching tool for basic amine reactions, and in industrial settings, it flows through whole production lines, feeding into the creation of more complex materials that touch daily lives without much fanfare.

New research looks for ways to coax better efficiency out of amine synthesis, greener catalysts, and, above all, less environmental fallout. Universities publish on high-performance gas chromatography and mass spectrometry methods for quantifying trace amounts of isopropylamine residues in soil and water, which shine a light on environmental fate. I’ve seen researchers focus on selective catalytic routes to avoid more hazardous by-products, an approach that catches funding attention and stays grounded in sustainability goals. Teams developing new drug molecules also test related amines for bioactivity, flipping through chemical catalogs to find which basic amine structure could fit best. These efforts build on an old molecule’s potential to answer newer, tougher questions.

Toxicology reports warn of acute effects at moderate exposures: headaches, nausea, respiratory irritation, and skin burns. Animal studies show adverse effects from both inhalation and ingestion, with symptoms scaling fast with increasing dose. Long-term research on humans lags behind, so safety routines don’t let up. Chronic exposure limits and workplace standards come from regulatory agencies like OSHA and NIOSH, which set airborne exposure at low values and demand direct monitoring in workplaces. Wastewater containing small amounts receives treatment to avoid ecological harm, since aquatic species show sensitivity to even minor amine pollution. I remember a spill protocol drill where a few drops on the floor got treated like a full-blown emergency; such drills impress the seriousness of the risks on everyone involved.

Future work on 2-Propylamine circles around greener production and smarter uses in medicine. Firms invest in bio-based synthetic paths, hoping to shrink the overall carbon footprint and avoid the sharp environmental edges that come from older chemical practices. In drug discovery, researchers keep an eye out for new derivatives that show better specificity or reduced toxicity, betting that simple amine frameworks may still surprise with fresh therapeutic activity. Manufacturing circles watch for methods to recycle amine-containing waste streams, and policymakers press for more transparent handling practices. The close link between small amines and major industries means there’s a long road ahead, with opportunities for safer, cleaner, and more purposeful applications still waiting just past the horizon.

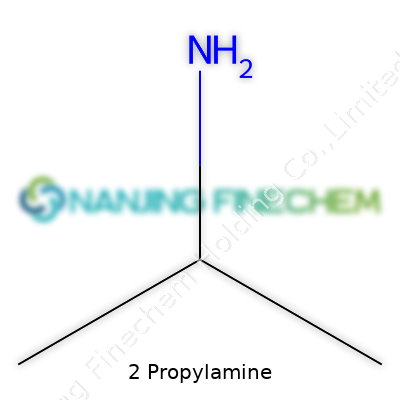

Every time I look at a chemical name, old habits from high school chemistry come right back. I figure out its formula like I’m checking a puzzle. Take 2-Propylamine—it goes by isopropylamine too. On paper, it reads as C3H9N. Each molecule packs three carbon atoms, nine hydrogen atoms, and a nitrogen atom. Scientists often mark up chemical names like chefs swap out ingredients, but at its core, 2-Propylamine stays simple and direct.

Grab a calculator, add up those atomic weights: three carbons at about 12.01 each, nine hydrogens at 1.008, and a nitrogen at 14.01. You hit roughly 59.11 grams per mole—a tidy figure. Maybe this number looks dry to most, but it becomes the difference between measuring out amounts or getting a reaction to work right in the lab. Too much or too little can throw off whole processes, and I’ve had more than a few headaches over mismatched weights in the past.

These aren’t just random facts to plug into a test. The properties of molecules tie into so many industries that quietly run modern life. Labs, production floors, even fields—somewhere, someone leans on information like this. Years ago, I spent time in a shop where mixing chemicals got us new coatings. Customers never asked the names, but if I missed the right amine or botched a measurement, the batch failed, money burned, and we started again.

You spot 2-Propylamine in rubber manufacturing and the making of pesticides. Folks in oil refineries use it too. In each case, nailing the details means safer storage, more reliable end results, and less waste along the supply chain. Years of hands-on fiddling have convinced me that mastering the chemistry cuts down on expensive surprises.

Working with small amines, like this one, brings a sharp smell that sticks in your nose and clothing. You mess up the ventilation, and headaches follow fast. I’ve seen folks get careless with storage or toss a half-used drum where moisture can seep in. A little extra training on what the numbers mean and how they connect to safe handling cuts down on emergencies.

Hazards aside, another issue comes from supply. Chemicals like 2-Propylamine swing in price. When times get tight, cheap substitutes float around. Some labs keep running with knock-off supplies, and that wrecks trust down the line. I’ve found that sharing clear records of source, quality, and formula keeps standards high and second-guessing low.

So, it might look like just another string of letters and numbers, but more lives and livelihoods hinge on chemical specifics than most folks ever realize. From the formula to the weight, every small detail plays out in bigger ways—sometimes quietly, sometimes as a headline.

Whenever people talk about industrial chemicals, the names run together. 2-Propylamine sounds cold and disconnected from daily life, but its story stretches out in more ways than most realize. I first stumbled on it flipping through safety sheets for a manufacturing job, and the name stuck—probably because it kept popping up in places where no one talks about chemistry degrees.

Factories never stop looking for materials that can speed things up, hold things together, or help make complicated stuff without breaking the bank. 2-Propylamine often steps in as a team player for chemical synthesis. Think about building new medicines—a lot of clever drug designers turn to amines (that’s the family 2-Propylamine belongs to) when they need something that connects bigger molecules together. When pharmaceutical labs explore new antibiotics or treatments, they throw molecules like 2-Propylamine into the mix. It becomes part of a bigger chain, shaping the final medicine.

Pesticide manufacturers follow a similar path. Many crop protection products begin with small molecules before they get altered and tested to protect fields. A bunch of these new molecules start their journey with 2-Propylamine. It’s like hiring a reliable builder to lay down the foundation of a house.

I’ve watched workers in coatings plants measure out all sorts of amines, and 2-Propylamine crops up on ingredient lists. In paint, it helps the final product resist chipping and sticking. It also shows up in making cement additives, where nothing seems glamorous but a lot depends on chemical helpers like this.

Sometimes it’s surprising where you notice the same tool crop up—in rubber processing, for example. The folks producing tires and industrial seals often rely on specific amines to manage the properties of the finished rubber. It helps make these materials last longer and stand up to stress, which probably keeps stuff like car tires rolling longer than people expect.

Plenty of chemicals used in industry get a reputation for causing headaches, not just for their smell, but safety reasons too. 2-Propylamine is flammable and gives off irritating vapors. I’ve seen people ignore safety gear because handling barrels gets repetitive, but even a quick splash can mean burning skin or runny eyes. Storing and using it safely isn’t something to gloss over.

Chemical producers and users talk a lot about storage systems, ventilation, and sealed environments so workers don’t end up with accidental spills. Simple solutions can make a real difference—labels that are impossible to miss, shower stations located closer to workstations, and better worker training. It isn’t about fancy fixes, just learning from mistakes on the floor and sharing those lessons widely so everyone goes home healthy.

2-Propylamine won’t be showing up on grocery shelves or filling headlines, but its fingerprints turn up in many places if you look around the supply chains. For companies still using chemicals like this, regular checks on exposure levels and substitutions for less hazardous options make sense. Not every industry can swap it out, but plenty have found ways to use smaller amounts or moved toward closed systems that keep fumes away from workers and the local air.

The humble 2-Propylamine reminds me that most things we rely on have a backstory in a warehouse or lab, handled by people who keep things moving. Paying closer attention to these building blocks—and the people handling them—leads to safer workplaces and better products every day.

Every job brings its own set of tools and risks. In a lab or a chemical warehouse, sometimes the greatest danger comes from a small bottle nobody hears about outside of work. 2-Propylamine lands in this category. Folks using it will tell you—the smell alerts you, the vapors grab your attention, and if you get complacent, things go sideways fast.

Handling 2-Propylamine reminds me of working with ammonia: it reaches out and stings your nose, so you know when the air isn’t clean. Exposure, even short-term, irritates eyes, nose, and lungs. Some people break out in a rash or cough up a storm. An accidental splash gets serious; the liquid eats at your skin and eyes, and, believe it or not, it can burn right through your gloves if you pick flimsy ones. I learned this watching a co-worker swat at a glove that never stood a chance.

Flammability adds another layer. The stuff vaporizes fast, forming mixtures that ignite with just a tiny spark. It’s not a “just keep the cap on” situation. In rooms with poor airflow, vapor lingers, creating a fire waiting for a cause. I recall a training drill where a beaker of 2-Propylamine needed only a static zap to start a panic.

Some rules aren’t negotiable. If you handle 2-Propylamine, glove up with stuff proven to hold up—nitrile or neoprene does the trick far better than standard latex. Eye protection keeps you from the worst mistakes. I’ve seen lab veterans wear full face shields after one too many close calls. Splash-resistant coats matter, so do chemical-resistant boots if your job gets splashy.

Ventilation could mean the difference between a simple shift and a trip to the hospital. Fume hoods aren’t optional. Working out in the open or with a janky exhaust risks everyone’s lungs, not just yours. I used to open the windows, thinking it was enough, but those days are gone after seeing a monitor peg off the charts.

A locked, cool cabinet, separate from oxidizers and acids, is worth every penny. The impulse to squeeze one more bottle in a shared cabinet sits deep. Yet, cross-reaction stories remind us to resist. Staff meetings turn dull fast, but the inventory session after a minor spill changed everyone’s tune in my crew. No more cramming bottles or ignoring that sticky residue.

Mistakes happen. Having a working eyewash and shower station nearby is not just regulation, it’s sanity. Nobody wants to play hero when fluids are flying. I once ran to the wrong end of a lab because the eye wash station was blocked by an old cart. After that, keeping these stations clear became my hill to die on.

Routine drives safety. Regular training, refreshers, and honest talks after close calls foster the right habits. Sharing near-misses makes everyone sharper. I keep checklists old-school style, not because I distrust software, but habits save the day long before bells and alarms do.

Respecting 2-Propylamine, like any hazardous chemical, runs deeper than memorizing a data sheet. It means learning from each other, speaking up when storage slips, and refusing shortcuts. That’s what keeps folks going home safe at the end of the day.

Ask anyone who’s worked in a chemical lab about 2-Propylamine. The name alone brings a caution sign to mind. This stuff—a clear, colorless liquid—packs quite a punch with its strong, fishy smell. Having spent time in research labs, I’ve seen firsthand what happens if you don’t store certain chemicals right. One spill is all it takes to clear out a room and leave your nose tingling. 2-Propylamine reacts quickly with water and acids, and it produces flammable vapors. That’s not just a detail for textbooks; it’s something every storage decision needs to take into account.

Heat kicks up the volatility for many chemicals, and that’s true here. Lab stories circulate about how a storage area without air conditioning in the summer becomes almost unusable. 2-Propylamine needs a spot where the temperature sits out of sunlight, ideally below 25°C (77°F). Heat turns this chemical into an accident waiting to happen because its vapors can build up, ready to ignite with just a tiny spark. From what I’ve seen, nobody wants to mop up after an explosion—not to mention what it does to morale and budgets.

People sometimes forget how quickly the smell of 2-Propylamine invades a space. Without good airflow, you’re left with a suffocating environment where headaches show up fast. One lab I worked in had to get new fans installed after a rash of complaints. A tight space without good ventilation doesn’t belong anywhere near this stuff. Storage rooms need mechanical exhausts or vents to drag out those flammable vapors and keep concentrations down.

One time, a colleague stored a can of 2-Propylamine near a light switch. All it took was humidity and a worn-out switch to make everyone jumpy for the rest of the week. Flames, sparks, and hot surfaces don’t mix well with flammable liquids. The storage area should have explosion-proof lighting and no open flames nearby. Simple steps, but they keep emergencies at bay.

Containers for 2-Propylamine must be tightly sealed, preferably made of steel or glass. Plastic starts to break down with stronger amines like this one. I’ve run into drip trays catching spills under rusty lids, and it never gets less nerve-racking. Metal shelves and spill trays help catch leaks before they spread. Every lab that values safety keeps spill control kits within easy reach. It’s not paranoia—just common sense built from other people’s mistakes.

Clear labeling saves confusion. Accidents often happen not from ignorance, but from mix-ups. Keep 2-Propylamine away from acids, oxidizers, and even food storage. Mixing these chemicals causes violent reactions, and some folks only learn after a trip to the emergency room. I remember one incident where bottles sat too close, and incompatible vapors set off alarms in the middle of the night. Nobody enjoys those kinds of surprises.

If you handle 2-Propylamine at work, double-check storage routines. Review chemical compatibility charts and rethink where things sit in relation to each other. Install temperature loggers—just seeing those numbers day-to-day helps you spot problems early. Spend time on staff training. Walking people through storage spaces and explaining risks does more than handing out another page of safety rules.

Anyone who’s ever worked with chemicals for agriculture, pharmaceuticals, or industrial processes knows that purity shapes how things turn out. 2-Propylamine, a simple yet spirited amine, isn’t any different. Purity levels drive its real-world usefulness—think cleaner reactions, fewer headaches in quality control, and safer outcomes for workers and the environment.

I still remember visiting a small-scale lab where 2-Propylamine got used in organic synthesis. The chemist reached for the container, glanced at the label, and shook their head. “This stuff’s got too many side-products,” they grumbled. In that moment, grade became more than an abstract number. Minor differences in purity can throw a wrench into research, slow down manufacturing, or force businesses to chase down contaminants after the fact. Technical grade sometimes carries a lot of baggage—moisture, trace metals, maybe leftover solvents.

Commercial manufacturers often offer several grades. The chemical isn’t just sold as “2-Propylamine”—it comes with numbers attached: 95%, 98%, or even a “reagent grade” that promises above 99%. No surprise, there’s a price ladder too. Higher purity draws a steeper bill, but labs doing medicinal chemistry or microelectronic manufacturing rarely cut corners here. The tiniest contaminant can distort experimental results or compromise a device. Factories working with dyes or paints may go for a cheaper grade—functionality trumps extreme purity in those cases.

In global chemical trading, standards make sure buyers and sellers talk about the same thing. The American Chemical Society (ACS) sets criteria for many laboratory reagents. Other regions follow ISO or JIS rules. If an order says “ACS grade 2-Propylamine,” it spells out a concrete benchmark: no room for missing information. Companies put their labs to the test, drying the chemical and isolating it from side products through distillation or, sometimes, chromatography.

In places where regulators look the other way, some suppliers cut corners to meet demand. In those situations, industries end up carrying the risk. I’ve talked to engineers who spend weekends troubleshooting fouled reactors, only to trace the problem to low-grade 2-Propylamine laced with trace chlorides.

The way forward isn’t complicated, but it does call for practical thinking. Producers need to state the purity, impurities, and test methods right on a certificate of analysis. Customers shouldn’t settle for less. Anyone placing an order, especially outside their home market, ought to ask for documentation up front. If the application involves food, pharmaceuticals, or electronics, tighter standards bring peace of mind and help avoid expensive mistakes.

One positive trend: more buyers share purity requirements early in the procurement process and ask for sample testing before buying bulk. Open conversations between chemists, process engineers, and suppliers weed out a lot of guesswork. Trust builds as both sides realize what's at stake, whether it's human health or the reliability of a new chip.

Simple as it sounds, knowing what’s in each drum of 2-Propylamine saves everyone time down the road. No lab technician wants to rerun an entire batch, and no plant operator wants to explain why product quality slipped. Achieving that depends on understanding exactly what purity means in each context, recognizing how even minor impurities can shape outcomes, and keeping every step of the supply chain focused on clear, honest information.

| Names | |

| Preferred IUPAC name | propan-2-amine |

| Other names |

Isopropylamine sec-Propylamine 2-Propanamine |

| Pronunciation | /ˈproʊ.pəl.əˌmiːn/ |

| Identifiers | |

| CAS Number | 107-10-8 |

| 3D model (JSmol) | `3DModel: "CNCC"` |

| Beilstein Reference | 0635446 |

| ChEBI | CHEBI:42034 |

| ChEMBL | CHEMBL154324 |

| ChemSpider | 50413 |

| DrugBank | DB01941 |

| ECHA InfoCard | 100.007.847 |

| EC Number | 202-876-1 |

| Gmelin Reference | 7717 |

| KEGG | C02288 |

| MeSH | D017637 |

| PubChem CID | 7923 |

| RTECS number | UJ4375000 |

| UNII | 1S8T70J3H5 |

| UN number | 1277 |

| Properties | |

| Chemical formula | C3H9N |

| Molar mass | 59.11 g/mol |

| Appearance | Colorless liquid |

| Odor | ammonia-like |

| Density | 0.722 g/mL at 25 °C |

| Solubility in water | Miscible |

| log P | 0.51 |

| Vapor pressure | 316 mmHg (at 20 °C) |

| Acidity (pKa) | 10.7 |

| Basicity (pKb) | 3.36 |

| Refractive index (nD) | 1.384 |

| Viscosity | 0.33 mPa·s (20 °C) |

| Dipole moment | 1.15 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 198.7 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -14.8 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3896.7 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02, GHS07 |

| Signal word | Danger |

| Hazard statements | H226, H302, H311, H314, H332 |

| Precautionary statements | P210, P233, P240, P241, P242, P243, P261, P264, P271, P280, P302+P352, P304+P340, P305+P351+P338, P311, P312, P321, P330, P337+P313, P362+P364, P370+P378, P403+P235, P405, P501 |

| NFPA 704 (fire diamond) | 3-3-2-A |

| Flash point | 40 °C (104 °F) |

| Autoignition temperature | 430 °C |

| Explosive limits | 2.1–10.4% |

| Lethal dose or concentration | LD50 oral rat 820 mg/kg |

| LD50 (median dose) | LD50 (median dose) of 2-Propylamine: Rat oral 650 mg/kg |

| NIOSH | SK |

| PEL (Permissible) | PEL = 25 ppm (as an 8-hour TWA) |

| REL (Recommended) | 25 ppm |

| IDLH (Immediate danger) | 700 ppm |

| Related compounds | |

| Related compounds |

Amylamine Isopropylamine n-Propylamine |